Basic workshop equipment for electronics engineers and developers

Whether you're a hobbyist, maker, or professional developer, a well-equipped workshop is the basis for precise, safe, and efficient work. But which equipment is really worth investing in? Which tools, measuring devices, and safety solutions are indispensable – and where can targeted upgrades provide greater convenience and better results? We provide information on the must-haves that no electronics workshop should be without, what to look for when making your selection, and how you can take your projects to the next level with high-quality equipment.

The basics – organization, power supply, lighting

Every good workshop starts with solid basic equipment. After all, if you’re searching for components, working with an inadequate power supply, or soldering in semi-darkness, you’re not only wasting time—you’re also risking mistakes. With the right basics, you can create a safe, clear, and functional working environment.

Power supply

Stable, high-quality power supplies and batteries form the basis for successful developments in the electronics workshop. Whether power supply devices, voltage converters, transformers, rechargeable batteries, chargers, battery clamps, charging tongs, or batteries: invest in high-quality products from international manufacturers and benefit from their expertise.

Storage

Being organized is half the battle – this also applies to the electronics workshop. That’s why it’s highly recommended to purchase proper workshop equipment. After all, without structure, it’s easy to lose track of things. Various storage systems such as boxes, carrier frames, and assortment boxes help to keep things tidy. Signs and labels (with color coding if desired) enable direct and quick assignment.

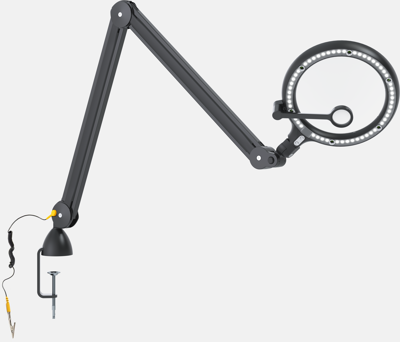

Lighting conditions

Fine soldering work or attaching tiny components to circuit boards – all this can only be done under optimal lighting conditions. An LED table lamp with a swivel arm and neutral white light color provides targeted lighting for the workplace – glare-free and flicker-free. An integrated magnifying lamp with magnification ensures even greater precision.

Measurement technology: measuring, testing, analyzing

Without precise measurement data, nothing works in electronics. Whether you want to test a simple circuit, debug a complex system, or track down a fault, reliable measurement technology is part of the basic equipment of every electronics workshop.

Digital multimeter

A multimeter measures voltage, current, resistance – and often more. Even compact entry-level models now offer functions such as frequency, temperature, and capacitance measurement or continuity testing. For more demanding applications, a multimeter with an interface for digital data acquisition is worthwhile.

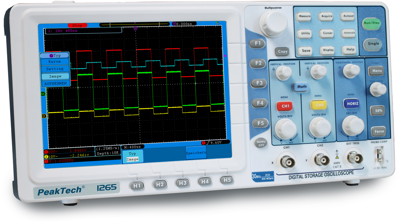

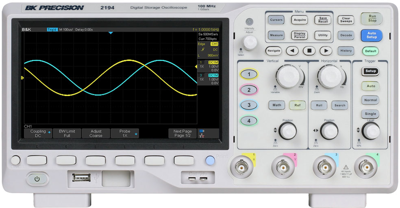

Oscilloscope

When voltage curves need to be visualized, there is no way around an oscilloscope. A digital storage oscilloscope (DSO) shows what is really in the signal. For tinkerers and developers, there are now compact tabletop devices with touchscreens or portable versions for on the go.

Soldering like the pros

Probably the most important tool for an electronics engineer: the soldering station. With a regulated soldering station, soldering temperatures can be set optimally. Analog models are in no way inferior to digital ones – however, digital products often offer greater accuracy.

High-quality soldering tips last longer than cheap products. That’s why you should rely on high quality from reputable manufacturers, especially in this area. For SMD work, soldering tips of 0.5 mm or less are recommended.

Regarding soldering accessories and dispensing needles: Sets containing the most important components are recommended for beginners. A so-called third hand including a magnifying glass and holding clamp is particularly practical when soldering or screwing small circuit boards.

You can find even more helpful information on soldering in the relevant magazine article.

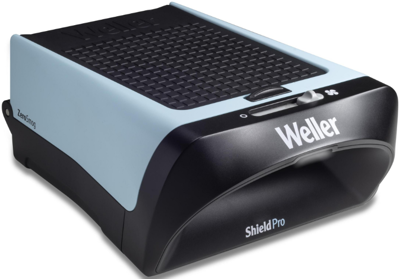

Protection & safety

Safety plays a central role in the electronics workshop. After all, you are working with electricity and heat. So if you want to set up or upgrade your workshop sensibly, you should not neglect this area.

Soldering in particular requires the right protection! We have summarized practical information on this topic for you in the magazine article.

Occupational safety

Safety goggles, hearing protection, and accessories: Safety comes first in an electronics workshop. We recommend keeping more than one set of products such as respirators and gloves in stock and ensuring that the products comply with standards and norms.

ESD protection

Electrostatic discharge (ESD) can cause irreversible damage to electronic components. When equipping your workshop, you should therefore consider protecting sensitive components. Reliable products in this area reliably prevent damage caused by electrostatic discharge.

Complete ESD protection includes:

- ESD table and floor coverings

- ESD work clothing

- ESD-compliant tools

- ESD gloves and wrist straps

- Shielding bags and antistatic bags

Ready for new projects

A well-equipped electronics workshop is more than just a hobby room or workplace—it is the basis for clean results, efficient processes, and safe developments. Whether it’s a power supply, multimeter, soldering station, or ESD protection: working with high-quality tools and well-designed accessories not only saves time but also avoids typical sources of error.

With the right equipment, prototypes can be realized more quickly, repairs can be carried out safely, and measurement data can be recorded reliably. For beginners and professionals alike, every sensible upgrade pays off in the long run.