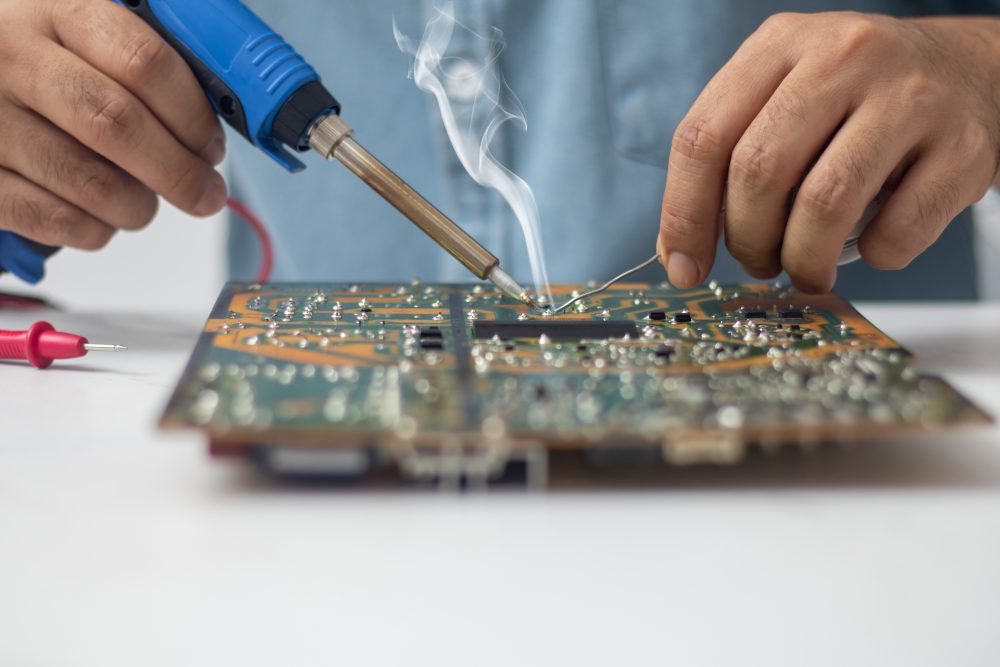

Toxic Solder Fumes: Why Protection is Essential

Toxic solder fumes are a serious health hazard for people who work or engage in soldering in the electronics industry. The toxic fumes can lead to respiratory illness, cancer and other health problems. Therefore, it is imperative that anyone working with solder take proper protective measures. In this blog, we will take an in-depth look at the risks of toxic solder fumes and how you can protect yourself.

What are the potential health risks of soldering?

Many of today’s dusts and fumes are harmful to your health when inhaled. Excessive exposure can lead to serious and long-term physical problems:

- Occupational asthma

- headaches

- Eye irritation

- Nosebleeds

- Sionasal cancer

- Throat infections

- Dermatitis and acne

- Damage to the respiratory tract

In this context, 30 minutes of exposure to particles in the air and gases per day is enough to cause health problems. That means about 110 hours per year or 14 working hours of exposure is enough.

Health risks from soldering

Lead-free soldering produces up to 250% more particles in the breathing zone than soldering with lead-based solder. Per cubic meter, 700 million tiny particles are emitted, which can enter the alveoli.

Health risks associated with adhesives

Adhesive fumes can cause skin irritation, drying of the skin, allergic contact eczema, respiratory and asthma problems.

Solvent health hazards

Vapors from organic solvents can damage the nervous system and cause reduced sensitivity and restless legs and arms.

Health protection with filtration systems and solder fume extraction systems

When soldering, it is of great importance to take precautions to avoid inhaling the harmful fumes and particles. After only 90 minutes of soldering with lead-free solder and a net mounted on the nozzle, it can be seen that the net was already completely clogged. This is where filter systems that bring clean air to the workplace can help, ensuring a safe working environment.

Filters of different degrees of permeability can be used to separate the particles and gases that are harmful to health:

- A fine dust filter M5/F7 filters fibers and pollen down to 10 μm and bacteria and pigments down to 5 μm and is suitable for standard applications and applications with higher flux content or fine dust content.

- An E12/H13 particle filter filters smog and asbestos dust > 1 μm and viruses > 0.5 μm and is suitable for applications with higher flux content or fine dust content.

- A broadband fiber filter filters gas and is suitable for applications with adhesive and solvent vapors.

Volume extraction can be used for hand soldering and machine soldering. For hand soldering processes at the soldering iron tip, direct extraction systems are used to absorb and filter the hazardous fumes.

The use of machine and robot exhaust systems increasingly protects particle-sensitive technical systems and components from contamination. The special filter systems retain or absorb particles and gases. This prevents damage to the workpiece (PCB) and sensitive machine parts.

Filter units for solder fumes from Weller

Weller filtration systems for surface extraction as well as direct extraction at the soldering tip, keep the A-dust values significantly below the required limits, thus guaranteeing clean air at the workplace, with minimal maintenance.

Surface extraction with Weller Zero Smog

The Weller extraction units are specially designed for designed for continuous industrial use. Due to the excellent workmanship, the special care taken in the design and selection of components Weller devices for surface extraction are particularly durable and reliable. The advantages of the Zero Smog range are:

- low noise level

- Automatic filter change notification system

- easy to operate & simple filter change

- separately replaceable fine dust pre-filter M5

- Activated carbon for effective glass cleaning

- Particularly large filter surface for longer service life

Direct extraction at soldering iron tips

In addition to surface extraction, Weller also offers soldering irons that are fitted with a suction tube on the handle. This means that the extraction opening is located directly above the soldering point during soldering soldering point and captures the entire soldering fumes. Soldering irons with integrated tip extraction can be connected to the Weller FE extraction systems. Further advantages of the solder fume extractor are:

- up to 2 soldering irons can be connected

- electric vacuum pump provides the necessary vacuum

- maintenance-free compressed air converter

- suitable for continuous industrial operation

- a compressed air cleaning filter additionally removes compressed air-related

odors