DIN 31051: Your Foundation for Efficient Maintenance in Electronics

To keep technical systems in top condition regarding their efficiency, operational safety, and longevity, careful maintenance is essential. DIN 31051 offers a structured approach with four clearly defined measures for this purpose. But how do you implement this standard in practice, and what tools do you need?

Table of contents

- Your Advantages with Standard-Compliant Maintenance

- Definition DIN 31051: The Foundation of Your Quality Strategy

- Maintenance according to DIN 31051: Prevention through regular checks

- Inspection according to DIN 31051: Check-up for Your Electronics

- Repair according to DIN 31051: Quick Repair for Defects

- Improvement according to DIN 31051: Continuous Optimization

- Classification by DIN EN 13306: Preventive vs. Corrective

- Benefits and Future Developments in Maintenance: Your Competitive Advantage

- Frequently Asked Questions about DIN 31051

Your Advantages with Standard-Compliant Maintenance

- Minimal downtime: Maximum machine availability through preventive measures.

- Cost savings: Avoiding expensive repairs and unplanned downtimes.

- Extended lifespan: Preservation of your valuable systems and components.

- Legal certainty: Compliance with relevant standards and regulations.

Definition DIN 31051: The Foundation of Your Quality Strategy

Maintenance according to DIN 31051 is a central pillar of quality assurance in the electronics and manufacturing industry. It describes the sum of technical, organizational, and administrative measures for maintaining the quality of a component or machine. The goal is to minimize downtimes and prevent expensive repairs or unplanned replacement actions. For the electronics industry, where precision and reliability are crucial, this approach is indispensable.

DIN 31051 divides maintenance into four core measures: Servicing, Inspection, Repair, and Improvement. This structure enables a systematic approach to planning, monitoring, and optimizing the condition of technical systems.

Suitable Products for Your DIN 31051 Strategy

Maintenance according to DIN 31051: Prevention through regular checks

In the area of maintenance, everything primarily revolves around ensuring that the target condition is maintained and that operational reliability is intact. This includes preventive measures such as oiling and greasing components, refilling operating materials and replacing wear parts. The focus is always on prevention and delaying signs of wear, as these inevitably cause costs. Continuous maintenance leads to the avoidance of extensive repairs and ensures the long-term functionality of technical components. Regular cleaning and adjustment of microchips, for example, are classic maintenance tasks in the electronics industry. In semiconductor production, this ensures the high standards of quality and reliability.

Your Tools for Maintenance according to DIN 31051:

- Cleaning agents & ESD protection: For the care of sensitive electronics and protection against electrostatic discharge.

View cleaning agents - Precision tools: Screwdrivers, tweezers, and special tools for fine adjustments.

View product range - Cable ties & cable management: For neat and maintenance-friendly cabling.

View product range

Inspection according to DIN 31051: Check-up for Your Electronics

To be able to act quickly and purposefully in the event of unexpected problems, regular thorough checks of the condition of a technical object are necessary. During inspection, the current condition of a maintenance object can be collected, recorded, and then assessed using a variety of techniques. Depending on the industry and the property to be checked, various methods are used to detect potential sources of error before damage actually occurs.

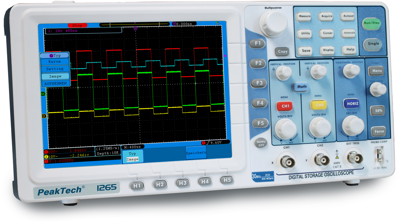

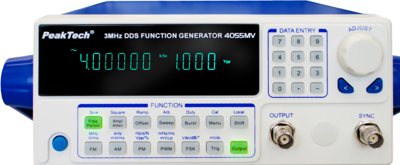

In printed circuit board manufacturing, for example, print quality is monitored via automated optical inspection (AOI). For the inspection of electronic systems, precise measuring instruments are indispensable for recording electrical parameters, temperatures, or mechanical deviations.

Learn more about AOI in our blog!

Measuring Instruments for Your Inspection (DIN 31051)

Further Inspection Aids:

- Endoscopes & microscopes: For visual inspection of hard-to-reach areas.

View product range - Voltage testers & clamp meters: For quick checking of electrical quantities.

View product range - Data loggers: For long-term monitoring of parameters.

View product range

Repair according to DIN 31051: Quick Repair for Defects

Efficient prevention of errors is always desirable. However, if damage and malfunctions have already occurred, it is important to remedy them quickly through repair measures. Repair includes all repair measures to restore the defined target condition of an object. In many cases, this involves replacing faulty or completely defective components.

Especially from telecommunications, it is known what far-reaching consequences the failure of network components can cause. To avoid image damage due to long downtimes and to restore stable network operation, reliable and quick repair is crucial.

Spare Parts and Tools for Repair:

- Semiconductors & microchips: For replacing defective electronics and repairing circuit boards.

View product range - Connectors & cables: For restoring connections and repairing cables.

View product range - Soldering technology & desoldering tools: For precise repairs to electronic assemblies.

View product range - Tools for cable assembly: Crimping tools, wire strippers, and cable cutters.

View product range

Improvement according to DIN 31051: Continuous Optimization

If there are no defects to be remedied, the measure of improvement comes into play as another component of maintenance according to DIN 31051. The aim is to adapt functioning systems and plants so that they work even more efficiently and reliably. These fine adjustments can result in increases in economic efficiency, production safety, and environmental compatibility.

Weakness analyses identify production sections in systems that are functional but whose maximum efficiency has not yet been fully exploited. Such measures are typical in the continuous improvement of automated production lines, such as in the manufacture of printed circuit boards. This can mean replacing components with more energy-efficient models or integrating smart sensor technology.

Products for Improving Your Systems:

- Sensors & actuators: For more precise control, monitoring, and automation.

View product range - PLC controls & HMIs: For optimized automation processes and better visualization.

View product range - Energy efficiency components: Such as LFP batteries or efficient power supplies to reduce energy consumption.

View product range - Industrial IoT modules: For networking and data acquisition for predictive maintenance.

View product range

Classification by DIN EN 13306: Preventive vs. Corrective

In addition to the classic DIN 31051, another standard related to maintenance is relevant: DIN EN 13306. It divides the individual measures into two overarching main categories, namely preventive and corrective maintenance. Although they are linked at different points in the overall maintenance process, they only achieve the desired effect in combination with each other.

Preventive Maintenance: Proactive Against Failures

Preventive maintenance summarizes all work steps that identify potential failures and defects early on, before they occur. Specifically: servicing and inspection. Particularly in medical technology, sensitive sensors and the circuits of complex systems require this proactive approach for reliable quality assurance.

Corrective Maintenance: Quick Response to Malfunctions

Corrective maintenance refers to troubleshooting after malfunctions and failures that occur despite preventive measures – i.e., repair. This can be explained by the repair of defective microchips in computer hardware. Although preventive measures have been taken to minimize susceptibility to defects, occasional malfunctions are unavoidable. Replacing the defective chip is therefore a repair measure that is assigned to corrective maintenance.

Benefits and Future Developments in Maintenance: Your Competitive Advantage

To summarize: The maintenance standards DIN 31051 and DIN EN 13306 are crucial for quality assurance in the electronics industry. They ensure maximum operational readiness and extend the lifespan of devices and machines. Consequently, substantial cost savings can be achieved.

Due to the increasing importance of the Internet of Things (IoT) and the growing automation of various technical processes, significant developments are currently emerging in the field of maintenance. Concepts such as Maintenance 4.0 and Predictive Maintenance are playing an increasingly important role and enable intelligent, predictive maintenance – a clear step forward in terms of system performance and economic efficiency.

Learn more about Maintenance 4.0

Ready for the Future of Maintenance?

Optimize your processes with the right components from Bürklin.

Discover our entire maintenance product range now!

Bürklin delivers: Your Advantages with Bürklin

- Expert advice: Our specialists support you in selecting the right products for your maintenance strategy.

- Wide range: Over 70,000 items from leading manufacturers available from stock.

- Fast delivery of in-stock items

- Quality & reliability: Your partner for high-quality electronic components since 1954.

- Attractive conditions for large orders and framework agreements.

Frequently Asked Questions about DIN 31051

What is the goal of DIN 31051?

The primary goal of DIN 31051 is to ensure and restore the functional condition and optimize technical systems. It serves to minimize downtimes, extend the lifespan of systems, and increase operational safety, ultimately leading to significant cost savings.

What four measures does DIN 31051 comprise?

DIN 31051 divides maintenance into four main measures:

- Servicing: Measures to preserve the target condition (e.g., cleaning, lubricating, adjusting).

- Inspection: Measures to determine and assess the actual condition (e.g., checking, measuring, monitoring).

- Repair: Measures to restore the target condition (e.g., repairing, replacing defective parts).

- Improvement: Measures to increase functional safety or efficiency (e.g., modernization, optimization).

What is the difference between DIN 31051 and DIN EN 13306?

DIN 31051 is a German standard that defines the basic measures of maintenance. DIN EN 13306 is a European standard that establishes a more comprehensive terminology for maintenance and categorizes the measures of DIN 31051 into the overarching categories of “preventive maintenance” (servicing, inspection) and “corrective maintenance” (repair). Both standards complement each other and are relevant for holistic maintenance management.

What role does maintenance play in Industry 4.0?

In Industry 4.0, maintenance is transforming from a reactive to a proactive and predictive discipline (Predictive Maintenance). Through the networking of machines (IIoT) and the use of machine learning, machine data can be analyzed in real time to precisely monitor the condition of systems and identify maintenance needs early. This leads to further minimization of downtimes and maximization of efficiency.

What products do I need for standard-compliant maintenance according to DIN 31051?

For standard-compliant maintenance, you need a variety of products that correspond to the four pillars of DIN 31051:

- Servicing: Cleaning agents, lubricants, precision tools, cable management products.

- Inspection: Multimeters, oscilloscopes, function generators, thermometers, endoscopes, data loggers.

- Repair: Semiconductors, microchips, connectors, soldering technology, tools for repairs.

- Improvement: Sensors, actuators, PLC controls, energy efficiency components, Industrial IoT modules.