Industrial Automation

Automation technology is revolutionising industrial processes, increasing efficiency and ensuring maximum precision.

Companies benefit from networked systems, smart technologies and optimised production. Prerequisite: top-quality components. An overview of the most important topics in this future-oriented area of application for Industry 4.0.

Control technology

Control technology is the central element of any automated system. Advanced solutions in this area enable smooth interaction between individual devices, minimise sources of error and improve efficiency. The control technology precisely coordinates all machines and processes and ensures efficient operation in real time.

Various control systems are used for this. The most important: programmable logic controllers (PLCs).

PLC – the successful successor to connection-programmed control devices

These robust and flexible devices are digitally programmed in advance and are used to control and regulate industrial plants. Programmable logic controllers (PLC) and industrial PCs (IPC) control and regulate production processes with the utmost precision, enable seamless communication between system components and ensure that specific tasks are carried out correctly. PLCs are an alternative to hardwired/connection-programmed controllers.

It is true that PLCs require significantly more qualitative infrastructure, such as programming devices and various software and data backups. However, the advantages over the previous technology still outweigh the disadvantages.

PLCs are generally considered to be more compact and flexible than connection-programmed controllers, are designed for more complex applications and impress with their reliability and fast error analyses. Most systems also have modifiable control logic and can thus be adapted to different environments.

Future-oriented technologies: Advanced developments such as adaptive controllers, which can be flexibly adapted to changing conditions, and PLC systems with integrated artificial intelligence, illustrate the potential of modern control technologies and set new standards in automation.

Learn more about PLCs

Process automation: precision in complex environments

Modern process automation ensures the precise control and monitoring of complex processes. Smart sensors, AI-supported systems and networked control systems optimise manufacturing processes and ensure maximum productivity.

Time-consuming and error-prone manual tasks can be delegated to software bots thanks to robotic process automation (RPA), making processes even more efficient and saving not only time but also costs.

Control technology & Process automation: high-quality products from Bürklin

Open Source Hardware: Democratisation of automation

Free blueprints for industrial hardware: The publicly accessible instructions are open for anyone to edit and further develop. However, there are a few things to consider here: Open Source-compatible licences should be used – including the release of commercial use – and various design files should be available.

Furthermore, parts lists, assembly instructions and various data are supplied and both a versioning system and an issue management system are used; thus, appropriate expertise is required.

Another requirement is the publication of a contributor's guide that explains how to collaboratively develop the hardware. Open Source Hardware can be found in the following areas:

- Electronics: e.g. PCB-based design

- Chip design: including complete open source software stacks

- Mechanics: including machine tools and vehicles

- Mechatronics: including medical devices

- Robotics: including entangled open source robotic systems made of mechatronics, AI and control software

Standards & guidelines: Safety and standardisation in automation

Various committees and organisations, including the European Committee for Standardisation (CEN), develop standards specifically for the field of automation and machine safety. A distinction is made between type A, type B and type C standards.

- Type A standard: Type A standards define fundamental concepts, terminology and design principles and form the basis for further standards. However, they do not establish a presumption of conformity, which would be crucial for liability issues. An example is the basic safety standard EN ISO 12100:2010 for risk assessment and risk reduction for machines.

- Type B standard: Type B standards are more specific and deal with aspects of machine safety. They are applicable to many machines.

- Type C standard: Type C standards relate to a specific machine category. They often also refer to Type A or B standards. In the event of deviations, the Type C standard always applies.

Important standards in the field of automation are:

- ISO 13849 Parts 1 & 2 (design and integration of safety-related parts of control systems incl. software development in 13849-2 + validation)

- EN IEC 62061 (scope of application: complex machines, process industry) / IEC 62061 (Integration and validation of electrical, electronic and programmable electronic safety-related control systems) / EC/TR 62061 (Guidance for application of ISO 13849-1 and IEC 62061 in the design of safety-related control systems for machines)

- EN ISO 13849 (scope of application: conventional machines; discrete manufacturing)

- EU Machinery Regulation (2023/1230) – valid from 20 January 2027

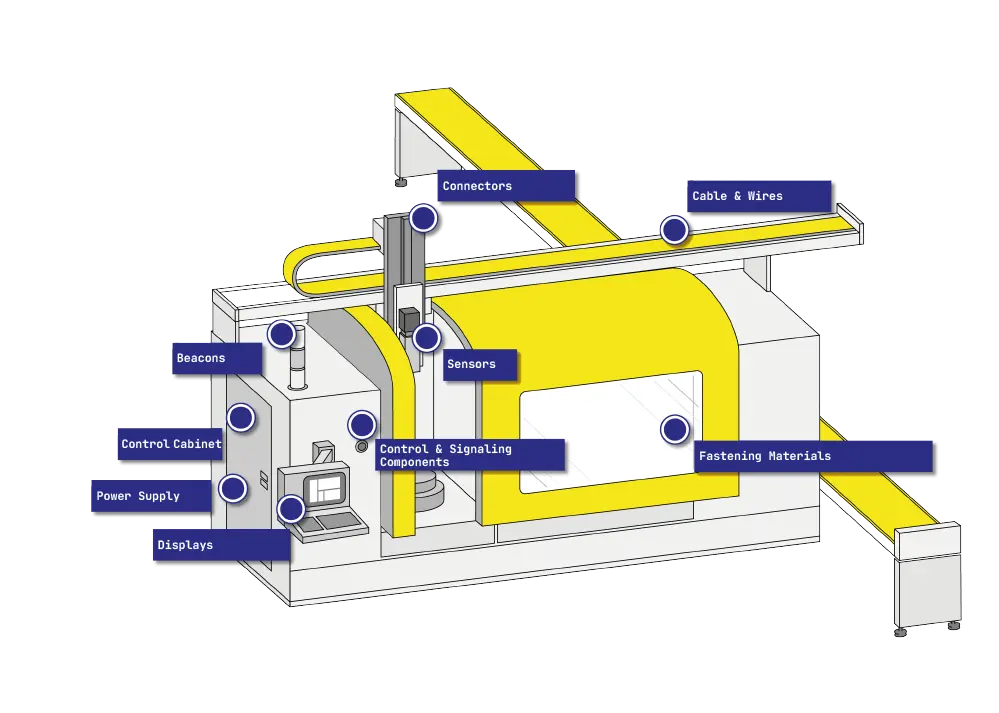

Smart Factories: Holistic solution of the future

With the advent of smart factories, industrial manufacturing is developing into a highly networked, intelligent system. This makes it an essential part of Industry 4.0. Machines, production facilities and buildings are digitally linked and communicate in real time. In addition, sensors and IoT technologies continuously collect data on environmental factors such as energy consumption, lighting and air quality. This information enables automatic optimisation, increasing efficiency and reducing costs.

Intelligent control systems allow maintenance processes to be planned in advance, safety standards to be improved and the entire operation to be made more sustainable. The connection between process and building automation not only creates technological advantages, but also increases competitiveness and improves the working environment.

Products for smart factories: Choose from our extensive range

Trends & future technologies: The future of automation

Industrial automation is developing rapidly, driven by groundbreaking technologies. Artificial intelligence (AI) and machine learning enable self-optimising systems that detect faults at an early stage and prevent failures. The most far-reaching changes are to be expected from the following developments.

- Digitalization: real-time data processing will become the standard – thanks to 5G technology. Fast and lag-free data transmission will continue to be essential for developments in robotics and networked systems in the future. The result: optimised processes and reliable maintenance forecasts.

- Cloud and edge computing: This is expected to lead to further improvements in data management, enabling companies to be more agile and efficient.

- Cobots: Collaborative robots that work closely with humans to take over monotonous tasks or to support them in demanding activities. In any case, human-machine interaction will play a central role in the future.

- Artificial intelligence: intelligent and flexibly adaptable manufacturing processes thanks to AI-based systems. The new generation of AI is even better at reading data, learning, recognising patterns and making autonomous decisions.

- Industrial Internet of Things (IIoT): the consistent networking of machines and devices enables data collection, analysis and control to be implemented in real time.

Maintenance & Services: The lifeline of automation

Automation technology, AI and reactive systems make maintenance and servicing more effective and predictable. Planning is simpler, more flexible and can be adapted much more individually to the company; work can be carried out more quickly, in a more targeted manner and with greater foresight.

Digital solutions are at the centre of Maintenance 4.0 – especially for larger and more complex plants and systems. This innovative form of machine service is made possible by AI, real-time data transmission and highly functional sensor technology.

Key indicators that play a role for sensors and software:

- runtime

- efficiency

- service life

Bürklin delivers: Your partner for customised solutions

Customer-focused service

70 years of expertise

Customised procurement solutions

Regional location

Solutions from our partners – for reliable automation technology

Find professional solutions from well-known manufacturers that make your automation technology even more efficient and reliable.

Finder relays for industrial automation

In order to be and remain an important player in the field of automation, reliable logic relays are needed. In this context, Finder offers OPTA, an innovative and proven solution that has now become even more flexible.

Expansion modules for OPTA relays

A range of expansion modules are now available for the OPTA programmable logic relay, a compact control system from electrical engineering specialist Finder. These significantly expand the product's capabilities, resulting in greater flexibility, productivity and versatility of use.

Thanks to the digital and analogue modules, it is possible to add inputs and outputs. The individual components can be connected to each other via AUX auxiliary connections: up to five modules can be connected to each OPTA. Various inputs and outputs that are relevant for automation processes are also covered.

Discover OPTA expansion modules

Measurement and testing technology solutions from GOSSEN METRAWATT

Optimise test sequences, increase precision: GOSSEN METRAWATT's robust products meet the requirements of modern automation technology. The claim: intuitive to use, versatile in functionality and ideally suited to industrial environments.

- The METRALINE MF installation tester was specially developed for standard-compliant testing in electrical systems and installations in accordance with IEC 60364-6, DIN EN 50110-1 and the corresponding sections of EN 61557. The device is easy to use with the help of images and audio signals – ideal for mobile use. Storage capacity: up to 1,000 measured values – including logging of test results.

- METRALINE EARTH – the expert solution for grounding and lightning protection systems. Professional grounding analyses are created using the Wenner method. The 3- to 4-conductor measurement used delivers precise results – including easy storage and logging.

- With the METRALINE VC SENSE multifunction voltage tester, GOSSEN METRAWATT offers a solution for non-contact current and single-pole voltage measurements. Whether voltage testing, resistance measurement, continuity testing or diode testing, the versatile measurement functionalities are optimally adapted to the high demands of industrial environments.

- METRAOHM 10 is GOSSEN METRAWATT's low-resistance measuring device with high-precision resistance measurement. The proven four-wire measurement method is used. The battery-powered test instrument is compact and easy to use thanks to clear menu navigation.

RAFI – smart IO technologye

Seamless communication between sensors/actuators and control systems: IO-Link is a key technology in automation technology. The promise: more efficiency, easier installation and better diagnostic options in industrial processes.

E-Box IO-Link from RAFI

The field-ready pushbutton box is used for decentralised operation of simple control tasks. Thanks to the IO-Link interface, it is possible to integrate any fieldbuses. The M12 connection and the included mounting clip make installation and commissioning easy.

No separate training is required. The illuminated pushbuttons provide clear tactile feedback thanks to the integrated MICON 5 micro pushbutton. Button colour, brightness and flashing modes can be individually adjusted depending on the application.

View E-BOX IO-Link seriesKnow How Hub Industry 4.0

All the information at a glance: discover our online magazine. We have compiled all the relevant information, innovations and developments on the subject of Industry 4.0 and automation in a clear and concise space.

Discover our know how hub

Frequently asked questions about automation technology

What is automation?

Automation refers to the use of technologies to control processes with little or no human intervention. In industry, this often means the automation of production and business processes using machines, robots and software solutions.

What is Industry 4.0?

Industry 4.0 describes the fourth industrial revolution, which is based on the digitalization and networking of production processes. This includes intelligent machines, the Internet of Things (IoT) and the use of real-time data to optimise processes. Automation technology is an essential part of this innovative and associated smart industrial operations.

What are the advantages of automation for companies?

Advantages are: cost savings through reduced manual work, increased efficiency through faster and error-free processes, maintenance security thanks to system-based predictions and planning, high product quality through precise manufacturing, and flexibility through adaptable control systems.

Which technologies play a key role in automation?

Technologies that play a key role are: artificial intelligence (AI) for process optimisation, robotics for automated manufacturing, Internet of Things (IoT) for networking machines, big data and analytics for data analysis and predictive maintenance, and cloud computing for global access to production data.

What challenges are there to introducing automation?

Challenges are, amongst others: high investment costs for new technologies, training employees to work with automated systems, cybersecurity to protect networked production systems, and integrating existing systems with new technologies.

What role does artificial intelligence (AI) play in automation?

AI makes it possible to analyse and independently optimise processes and avoid errors. Examples include predictive maintenance, in which machines automatically report maintenance requirements, and intelligent control systems that adapt production processes.

Automation products: What should you look out for when choosing them?

When selecting automation products, reliability, robustness, compatibility and user-friendliness play an essential role. Our team at Bürklin Elektronik will be happy to help you find the right product for your requirements.