Labelling in Industry 4.0 : Technological innovation and digitalisation at HellermannTyton

In an increasingly digitalised world, innovative technologies are essential to increase efficiency and remain competitive. HellermannTyton is setting standards here with smart Auto-ID solutions for industrial identification, traceability and process optimisation. By using the latest RFID and barcode technology, HellermannTyton enables seamless integration of digital processes in a wide range of industries - from the automotive industry to logistics and medical technology.

Automatic identification for optimised processes

The digitalisation of production and logistics processes begins with the unique marking and identification of components, machines and cables. HellermannTyton offers innovative solutions here:

- RFID transponders: contactless data capture for logistics applications, asset management and process optimisation.

- Barcode labels & printing solutions: Durable identification for components, cables and packaging.

- Industrial scanners & mobile readers: Fast and reliable identification in the field or in production.

Digital labelling solutions for industrial applications

In a digitalised industry, data, networking and efficiency count more than ever. But it all starts with something seemingly simple: clear, reliable labelling. After all, no digital structure can function without clear physical order. Whether in the control cabinet, on machines or in logistics, professional marking is the backbone of Industry 4.0.

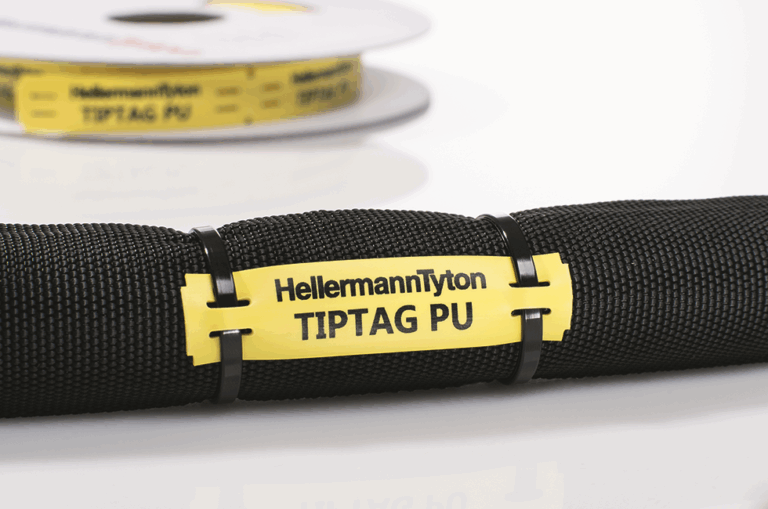

HellermannTyton offers a wide range of labels and printing systems for sustainable, durable and flexible marking:

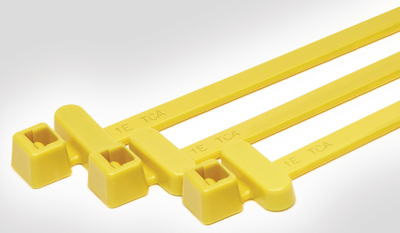

- Transponders, labels, hard tags, cable ties – resistant to extreme temperatures, UV radiation and chemicals.

- Thermal transfer printers – for high-precision printing results with maximum durability.

- Label creation software – for simple and flexible design of industrial markings.

Fast and flexible: manual marking on site

When things have to be done on the spur of the moment or no printer is available, manual marking offers a smart alternative. Pre-printed or blank labels can be marked directly with a permanent ink pen and adhere securely to cables, equipment or components.

Ideal for service teams and small volumes, HellermannTyton provides high-quality materials for every application – from self-laminating labels for harsh environments, to pre-punched panel plates for use in equipment manufacturing.

High-quality and efficient: thermal transfer printing at the point of use

For high-volume or complex marking tasks, thermal transfer printers combined with TagPrint Pro software offer a powerful system which enables data import, standards-compliant layouts and seamless process integration – all on site.

Whether heat shrink tubing, labels or cable markers, the print quality is durable, precise and even suitable for extreme industrial conditions.

Robust marking for long-lasting information

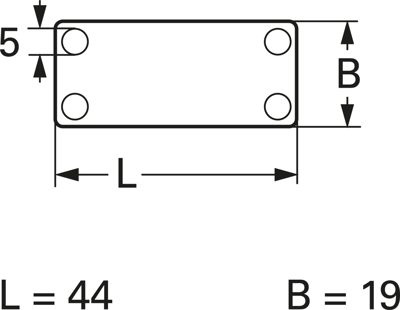

Plastic or metal plates are the preferred choice where information must remain visible over time – like type designations or inspection markings. They can be securely attached with cable ties and printed in-house, improving efficiency in both mechanical and electrical engineering.

Keeping things organized in the control cabinet: Safety through structure

Clear labelling in the control cabinet saves time, reduces errors and boosts safety. The Helatag series from HellermannTyton delivers a coordinated solution with matched carriers and markers for terminals, devices and cables. Paired with thermal transfer printers, even complex series labelling can be implemented quickly and in compliance with standards.

Making safety visible

Markings that warn, inform or guide help ensure operational safety. HellermannTyton offers a broad range of standard-compliant warning and inspection labels – ready to personalise for use on machinery, during maintenance or for statutory inspections such as DGUV testing.

Smart maintenance & predictive maintenance

Digitalisation offers companies new opportunities for process monitoring and maintenance optimisation:

- RFID-supported asset management minimises downtime and optimises service cycles.

- Cloud-based data management ensures seamless documentation and traceability.

- Intelligent sensor technology supports digital workflows in production processes.

RFID technology: digital transparency meets robust practice

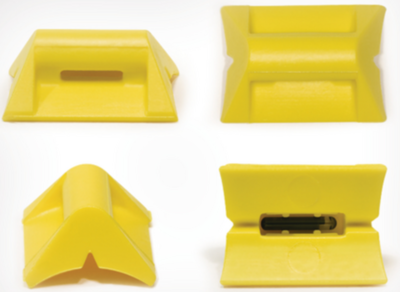

RFID transponders with integrated sensors bring a digital edge to industrial identification. These tiny chips provide unique object IDs and record data like temperature, pressure or humidity – wirelessly and in real time.

Designed to perform in demanding conditions – from moving equipment and hard-to-reach areas to autoclaves – RFID helps cut wear, reduce maintenance and support reliability. Passive variants operate without a power source, while semi-passive versions offer extended data storage and battery options for long-term monitoring in logistics, production or building services.

Backed by decades of plastics expertise, HellermannTyton RFID solutions are easy to integrate with cable ties, screws or rivets. Our advantage: the fusion of robust construction, smart features and practical installation – unlocking new potential for quality assurance, maintenance and automation.

Benefits of digitisation with HellermannTyton

- More efficient processes: Automatic identification reduces manual errors and saves time.

- Maximum safety: clear identification prevents mix-ups and facilitates traceability.

- Sustainable solutions: High quality materials reduce resource consumption and minimise waste.

HellermannTyton uses innovative technologies to help companies optimise their digital processes and be prepared for the future.