Industrial Internet of Things: A Compact Guide

The manufacturing industry is undergoing a profound transformation. With the advent of the Industrial Internet of Things (IIoT), a new technology is reshaping production, maintenance, and logistics. But what exactly do terms like IIoT, industrial IoT, or Industry 4.0 mean? This guide provides a clear overview of the key concepts behind the Industrial Internet of Things. It highlights common applications and explains by using real-world examples how companies can benefit from connected industrial systems.

What Is the Industrial Internet of Things?

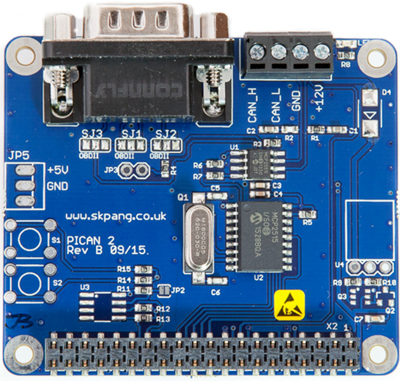

The Industrial Internet of Things, or IIoT, refers to the networked integration of machines, equipment, and sensors in manufacturing environments. Unlike the general Internet of Things (IoT), which is commonly used in everyday applications like smart home devices or connected vehicles, IIoT focuses specifically on production processes, equipment control, and overall factory efficiency.

IIoT enables companies to collect, analyze, and leverage vast amounts of data from machines and systems. This opens up entirely new possibilities: production lines can be monitored in real time, maintenance needs can be detected early, and the entire value chain can be optimized.

IIoT is a core component of Industry 4.0 – a term that refers to the comprehensive digital transformation of manufacturing.

IIoT – The Current Landscape

The Internet of Things is clearly on the rise. Recent figures show that 86% of manufacturers are planning to expand their IoT infrastructure. The industrial sector reflects a similar trend: as of the end of 2023, 75% of industrial companies had already implemented IIoT solutions or were in the process of doing so – up from 67% the previous year.

Where Is IIoT Used in Industry?

IIoT is deployed whenever real-time data from production environments needs to be captured and processed.

Typical use cases include:

- Condition monitoring of machines

- Predictive maintenance

- Optimization of production workflows

- Automation and process control

- Quality assurance and traceability

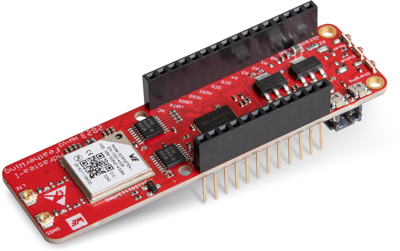

Thanks to connected sensors and smart control systems, production data can be collected directly in the manufacturing buildings. This data is then analyzed, either in the cloud or on edge devices, providing actionable insights to optimize processes. Industrial IoT significantly helps reduce downtime, improve resource efficiency, and lower operating costs.

What’s a Real-World Example of IIoT?

A classic example of IIoT is predictive maintenance. In a production facility, machines are equipped with sensors that monitor parameters like temperature, vibration, or power consumption. This data is continuously analyzed. If the system detects any deviation from normal operation, it automatically triggers maintenance – preventing unexpected equipment failures.

Why IIoT Matters

The Industrial Internet of Things plays a vital role in digital transformation. IIoT applications make it possible to optimize not just individual production steps but entire value chains. Companies that integrate IIoT into their operations can respond more quickly to changes, reduce production costs, and enhance their competitiveness.

Industry 4.0, IoT, and IIoT are closely interconnected. While Industry 4.0 describes the vision of a fully digitalized and interconnected factory, IIoT provides the technological foundation to make that vision a reality. Industrial IoT brings transparency, flexibility, and efficiency – key factors for economic success in an increasingly connected world.

IIoT – The Technology Driving the Future of Industry

The Industrial Internet of Things is no longer a futuristic concept. An increasing number of manufacturers are adopting IIoT to modernize production, cut costs, and conserve resources. IIoT is the key to successfully implementing Industry 4.0 – and to building a strong, competitive industrial sector. The numbers speak for themselves: those who invest in IIoT today are laying the groundwork for a sustainable and future-proof manufacturing strategy.