Engineering Office Koch

"For more than 35 years, we have found in Bürklin Elektronik the ideal component and tooling partner for our test system"

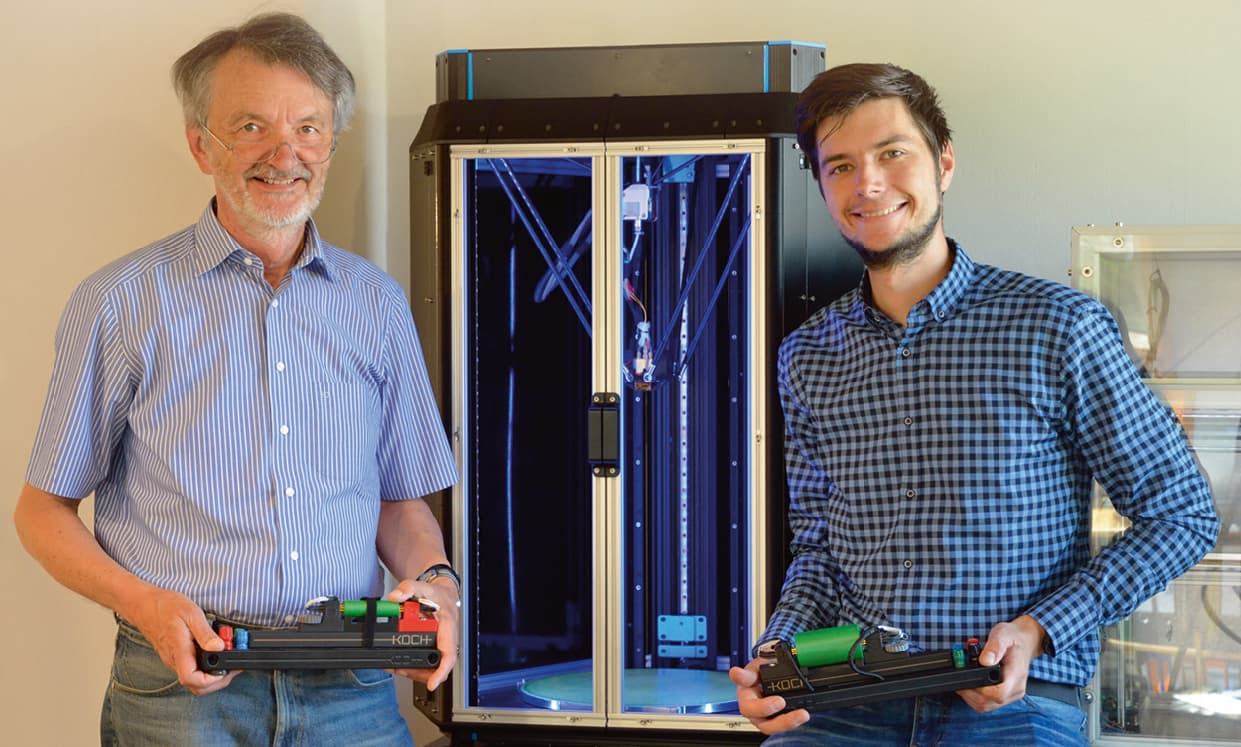

Engineering Office Koch has specialised in testsystems since its foundation 1986.

Since then, founder Georg Koch has bought a large part of his tools and components from Bürklin Elektronik.

For more than ten years, battery cell test systems have made up the majority of the engineering company‘s portfolio. Initially, the company started with cylindrical cell adapters. In the meantime, Koch pouch cell adapter systems and modules are also used by a large number of well-known customers in battery production, assembly and electromobility. The graduate engineer has developed each of these individual and extremely high-quality and robust battery test equipments himself together with his son. The engineering company‘s portfolio is constantly adapting to the needs of the market.

The decisive factor for Koch‘s cooperation with Bürklin Elektronik was the very large and complete range of products offered by the distributor Bürklin Elektronik, together with its rapid availability and consistently high quality from brand manufacturers. ”Be it passive components, semiconductors, high-temperature-resistant stranded wires and cables, housings, plugs and sockets, binding posts and hand tools - pliers, soldering tools.... - almost everything is available in small quantities and extremely reliably on the next working day - this is important for us to be able to push our developments and react very individually to customer needs,“ says Koch.

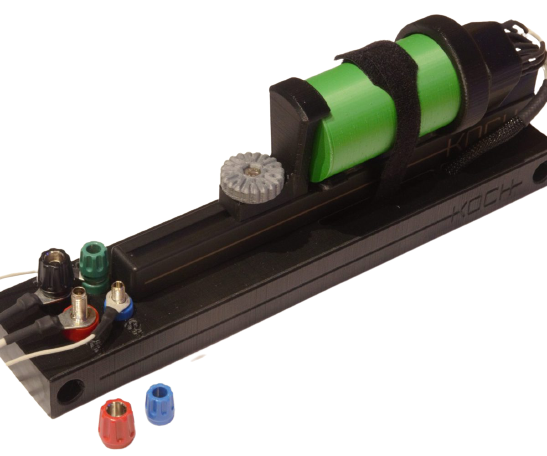

This is complemented by expert advice and excellent service when there is a need for special solutions or special requirements. The most recent example - the removable pole terminal. While the pole terminal manufacturer attached great importance to the insulated head being captive and therefore flanged it on, this caused a great deal of additional work for the battery cell adapter; different cables would have been needed because the ring cable lugs supplied as standard on the cable sets of the battery testers could not be mounted on the pole sockets of the system. Bürklin Elektronik consulted the manufacturer SKS/ Hirschmann and within a few days the feedback was received that the terminals could also be manufactured and supplied with unscrewable heads.

The problem was permanently solved - even for small quantities. Since then, Engineering Office Koch has been purchasing custom-made pole sockets from Bürklin Elektronik. The only downer is somewhat longer delivery times, as the terminals are specially made in their own, admittedly small, batches.

Every year, several hundred battery cell test adapters leave Koch‘s internal workshop in Unterschleissheim near Munich - and in similar other cases Bürklin Elektronik has repeatedly played a part in ensuring that the Koch brand promises of flexibility and robustness can be kept over the long term. This is because the layout of the Koch systems and implementation are highly individual: The units are mounted on a plate in modules of up to ten adapters. In-house production with the help of a 3D-FDM printer developed by Koch for the special technical PC plastics required in this application means that special solutions, for example for special cell sizes, button cells or higher currents, can also be implemented without any problems.

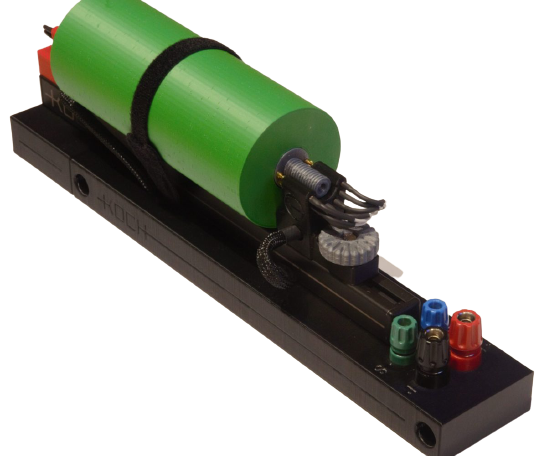

The cells are contacted via spring-loaded contacts made of gold-plated berillyum copper. Due to the higher currents, the measurement is carried out via four instead of two test contacts per pole and one test contact sense in both systems. In contrast to the standard version of the previous round cell adapters, cells of 18 to 46 instead of 14 to 30 mm diameter and 0-120 instead of 30-80 mm length can now be tested.

The connection to the test system is realised by means of pole terminals. The max. continuous current for the tests is 50 Amps, the max. current for up to ten minutes is 63 Amps. Alternatively, the connection to the test system can be made with safety laboratory sockets, as used in the standard solution for cells up to 30 mm diameter and 80 mm length. The maximum current is then reduced to 32 A. Due to the modular design, it is possible to mechanically connect up to 10 measuring channels to one assembly, which leads to high stability when equipping the adapters. The maximum size of the pouch cells is currently 220 x 270 mm, the maximum continuous current is 100 amperes. Larger cell dimensions and currents are possible on request.

When asked about the special know-how required for the development and construction of the test adapters, the experienced developer with more than 30 years of pro - fessional experience in the battery environment emphasises a whole series of points: One is the experience with the test environments in which the adapters are used, which led to the modular design. The other is the 3D printing technology. This would not have been possible without the expertise from 3D model construction in free-form design of Christian Koch, the son of the adapter developer and also an engineer. In order to be able to achieve today‘s flexibility, there was a gradual changeover from milled to 3D-printed and laser-cut parts from 2018 onwards. The aim was to meet the high requirements for mechanical stability with simultaneous high thermal stress, which has now been achieved well with high-quality engineering plastics. However, a standard 3D printer was not capable of this. What is needed is a filament drying system for the filament with a diameter of 1.75 mm, a controlled heated printing chamber, a special material for the print bed, as well as a heating and cooling system for the print head, which has to melt the filament within a narrowly defined temperature zone with a difference of 200 degrees over a distance of 15 mm. To achieve all this, a multitude of tests and optimisation steps were necessary.

| Version | Standard | High-Power |

|---|---|---|

| dimensions | 296 / 62 / 85 mm | 296 / 62 / 92 mm |

| electrical connections | safety sockets or pole clamp | pole clamp |

| number of test contacts per pole | current: 2 voltage: 1 | current: 4 voltage: 1 |

| diameter of test cell | 14 - 30 mm | 18 - 46 mm |

| minimum terminal diameter of test cell | 5 mm | 7,5 mm |

| length of test cell | 30 - 80 mm | 0 - 120 mm |

| maximum continuous current @ ambient temperature = 25 °C (contact surface: Cu bare) | 25 A | 50 A |

| maximum continuous current for 10 minutes @ ambient temperature = 25 °C (contact surface: Cu bare) | 30 A | 63 A |

| maximum ambient temperature without electrical load | 85 °C | 85 ° C |

Electrically, too, extensive investiga - tions of the current-carrying capacity were necessary to determine the optimum type and number of test needles and their arrangement. Optimising the current distribution between the test needles is at least as important. And the adapters also need good thermal management so that the test needles do not get too hot and, according to Koch, ”melt the plastic of the carrier from the inside“.

In the case of pouch cells, there are a few more aspects to consider: different materials of the cells or arresters in pouch cells also require a great deal of attention and have an influence on the contacts and arrangement of the test specimens. Are prismatic cells still missing? Here the mechanics are somewhat different and the cells are very large, the currents with up to 300/400 A very high. Of course, according to Georg and Christian Koch, it is also possible to build battery test adapters for this, but so far this has not been the focus of users. At the moment, the focus is rather on the cell size: Just in time for the an - nouncement by TESLA and other car manufacturers to immediately test larger round cells and presumably to use them in the future, Koch is offering the corresponding first highpower version of the round cell test adapters. With this, the announced new, large round cells with a length of up to 120 mm and a diameter of 46 mm can also be tested safely and precisely, either individually or in parallel in the measuring cabinet. Where a large part of the tools and components come from is known.

Contact

Engineering Office Koch

Dipl.-Ing. (FH) Georg Koch

Phone: +49 (0)89-22530086

Email: [email protected]

Website: ibk-ush.com