Intelligent Measurement and Evaluation Systems in Industry

Especially for automation, the precise and reliable collection of information by means of sensor technology is becoming increasingly important in numerous industrial sectors. Find out which measurement techniques and processes are available, what is important when measuring and in which industrial applications intelligent measurement and evaluation systems are becoming increasingly relevant.

Importance of measurement processes

In technical and automated processes, numerous physical quantities are recorded, converted and analyzed. This is based on the process of measurement: measurement is the comparison of an unknown physical quantity with a known physical quantity. For example, temperature, heat quantity, volume, voltage, current, resistance, inductivity or capacity.

With the expansion of automated processes in industry, the electrical measurement of non-electrical units is becoming increasingly important. A sensor converts the quantity to be measured into an electrical quantity and processes it. This allows the signal to be transmitted quickly and used further.

What are the measurement techniques and procedures?

There are four basic measurement methods: direct, indirect, analog and digital measurement.

- direct measurement: the measured value of a quantity to be determined is compared directly with a reference value of the same unit. This is referred to as a comparison method – for voltage or current measurements, for example.

- indirect measurement: In order to use this method, the relationship between the measurand to be measured and the measurand to be compared must be known (for example, in the case of resistance measurement using the current-voltage method).

- analog measurement: This measurement technique is given when the input variable is converted into an output variable by the process of measurement, by an instrument or a device. The output variable is proportional to the input variable.

- digital measurement: The measured value is converted into a digital value. This measurement technique is suitable, for example, for the transmission of data over longer distances. Low-loss signal transmission is made possible with the aid of fiber optic cables (FO).

A measured value is the value that is collected and output by a measuring instrument or measuring device. It provides a quantitative statement about a specific measurand. The result is shown on a scale or digit – for example on a display.

Quality of measurement: precise values matter

Deviations occur time and again during measurement processes. This is due to various causes: For example, the measuring device may have been incorrectly adjusted, or external influences affect the measured value. In order to minimize falsified values, reliable and precise sensors are needed so that the physical quantities can be recorded as accurately as possible.

In the field of industrial plants or processes, temperature sensors are often integrated to monitor the heat development in the electronic devices or machines. Especially in this field of application, precisely working sensors are important to ensure a smooth production process. The continuous collection and evaluation of the determined data (= measured values) thus prevents the failure of production lines, production machines or circuits.

Temperature sensors

All types of sensors that serve to measure temperature function according to two basic principles: Either they are contact thermometric (= touching) or pyrometric (= non-contacting) test or survey methods.

Typical applications of temperature sensors are electrical devices, temperature monitoring devices for welding or soldering work and the control (= activation and deactivation) of circuits.

Basically, the sensor measures heat or cold. It converts the measurement result into an electrical signal. This can be forwarded in the circuit and trigger appropriate actions. One example is the deactivation of a system if the temperature in the electronic device rises above a critical value. Therefore, temperature sensors play essential roles in monitoring and controlling the temperature in electrical devices.

Methods and possibilities of temperature measurement

- Expansion process (= thermal expansion): Determination of the geometric shape of a solid by the prevailing temperature.

- Resistance thermometer (= thermistors) use the temperature dependence of an electrical resistance to measure temperature.

- Thermo voltmeter are electrical conductors for detecting heat generation based on the thermoelectric effect.

- Infrared measurement: The infrared radiation of the object (IR radiation ranges from 0.7 μm to 1,000 μm) is measured.

H3: Advantages and disadvantages of temperature sensors

Vorteile sind …

… the precise measurement of temperatures.

… the application of the sensors at difficult to access measuring points and moving parts.

… the use in temperature ranges up to 800 °C.

Nachteile sind …

… the complex functioning of the electrical components.

… (often) the complicated integration into electronic systems and also the rather costly replacement of damaged sensors.

Product recommendation from Bürklin Elektronik: the KTY81 temperature sensor

Precision and reliability of the sensor are essential prerequisites for information acquisition and evaluation. Therefore, correspondingly high-quality products must be integrated into systems and electronic devices. The silicone temperature sensor of the KTY series of the NXP brand meets all requirements for efficient sensors.

The measuring accuracy of the sensor is very high. Also relevant: the positive temperature coefficient of the built-in resistor – which makes the sensor suitable for use in measuring and control systems. The functional range is between minus 55 °C and plus 150 °C.

Temperature sensors of the KTY81-110 series are suitable for quick replacement of the electronic component and its rapid assembly. These are plugged onto the printed circuit board by THT mounting and then connected to the circuit track by soldering.

Optical measurements in industry

Optical measurement technology is also an important efficiency factor for industry. In contrast to tactile measurement, optical measurement uses light to scan and detect objects without contact.

The entire measurement process is based on the physical principle of reflection and absorption. In this way, surface expansions can be completely determined, for example in aviation and medical technology. Components are precisely measured and inspected with the aid of the optical sensors. Several measuring points can be recorded in just a few seconds.

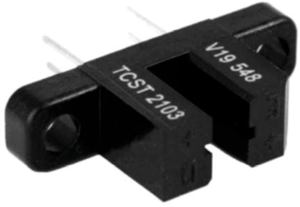

In the field of optical sensors, Bürklin Elektronik offers comprehensive product solutions, such as the optical sensor of the TCTST2103 product series with photo-transistor output. Also relevant in optical measurement technology is the EE-SX673 forked photoelectric sensor for precise measurements – for example, as part of the integration in motors, for speed detection.

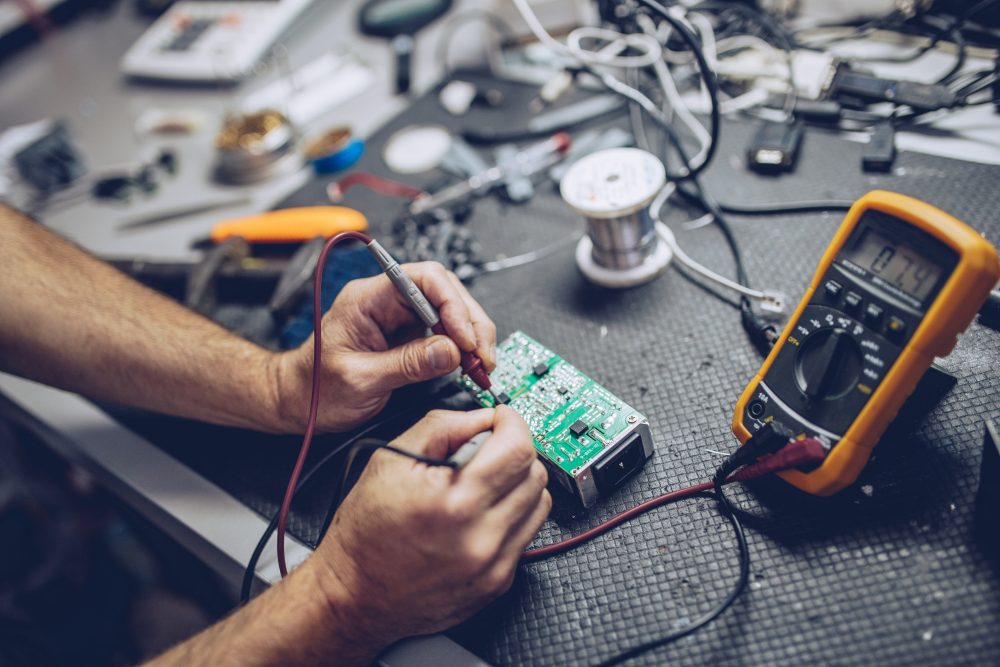

Test & Measurement and Sensors at Bürklin Elektronik

Bürklin Elektronik offers an extensive range of specific product solutions for various industrial sectors. Whether for aerospace, medical technology or the automotive industry, the high-performance measuring devices and sensors meet the diverse requirements in the respective fields of application.

Learn more about the test and measurement solutions and sensors at Europe’s leading distributor for electrical components and parts!

Are you looking for test clamps or test probes and other test accessories? Find the right accessories for your area of application!