Internet of Things & Industry 4.0: Trends 2023

The Internet of Things (IoT) has fundamentally changed the digital processes. In manufacturing in particular, developments in IoT have led to far-reaching innovations - for example, in the automation and robotics sector. What future developments are in store for the industrial sector? And: What trends can be expected in 2023?

Industry 4.0 – What is it?

First things first: What exactly does the term Industry 4.0 mean? And what does IoT have to do with it?

The term Industry 4.0 refers to the digitalization of production processes, more specifically: the development of networked systems and self-control technologies.

Until now, employees have been responsible for evaluating information provided by systems. In the future, however, machines will be equipped with special sensors and will be able to control communication and optimization processes themselves.

Thus, it is already apparent what Industry 4.0 and the IoT have to do with each other: The IoT enables the innovative developments in industry. Since the intelligent sensors and actuators are products manufactured specifically for industry, we also speak of the Industrial Internet of Things (IIoT).

The advantages of the innovative developments at a glance:

- reliable real-time analyses

- rapid exchange of information

- Simplification & optimization of production processes

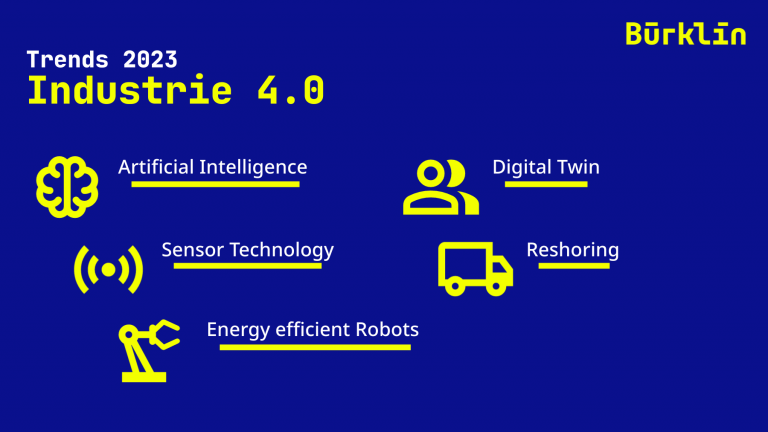

IIoT trends 2023

There are five key trends in the industrial sector that will continue in 2023:

Trend #1: Artificial Intelligence (AI)

The use of AI-supported systems is certainly a key driver of innovation – also in 2023. Especially in the field of robotics, there is great potential in the development of AI. The goal: to further optimize various manufacturing processes through targeted machine learning in order to be able to produce in an even more time- and cost-saving manner.

Manufacturers whose production processes are subject to many changes, such as in the case of a diverse and constantly changing product range, benefit the most. Through specifically adapted AI algorithms, cost-effective and rapid solutions are developed to simplify or improve the manufacturing process despite the many variables.

Developers predict: In the future, Artificial Intelligence will also play an increasing role in conceptualization and product development.

Trend #2: Energy-efficient robotics

In 2023, industrial companies will increasingly invest in energy-efficient and thus cost-saving technology – even in the industrial sector. No wonder: After all, the use of robotics contributes significantly to sustainable and energy-saving production.

The reason: for one thing, many industrial robots have energy-efficient technology - for example, specific controllers can convert the kinetic energy of the robotic elements into electricity and feed it back into the power grid.

Some robots also already have an energy-saving mode. In addition, the high speed at which the robots work increases the production rate. And that saves time – and energy.

Trend #3: Digital Twins and the Industrial Metaverse

Digital Twin technology has redefined the way industrial products are designed, manufactured and maintained. By virtually mapping objects or systems, entire production cycles can be simulated and updated in real time. Machine learning is providing increasingly concrete information about the manufacturing process. This data, in turn, serves as a basis for decision-making in various business matters.

The result: faster, more accurate, more agile and more efficient processes. Experts predict that digital twin technology can improve product quality by up to 25 percent. Around 17 percent of global manufacturers already use this technology.

Digital Twin technology can be combined with various Metaverse applications. Virtual reality can be used to mirror actual production environments, resulting in even more accurate data.

Trend #4: Further improvements in sensor technology

Specialized industrial sensors collect critical data and parameters such as temperature, position, pressure, force, humidity, distance or air quality. Such products, which are specifically designed for the manufacturing environment, are essential for further development in the field of automation and robotics. Further improvements in the product development of sensors and actuators can also be expected in 2023.

Trend #5: Reshoring & resilient supply chains

A trend that is less about the technology behind manufacturing processes and more about the sustainable availability of manufactured products is reshoring. In order to ensure resilient and reliable supply chains, the trend is moving away from offshoring (locating production facilities in emerging markets) back to moving production facilities back to the industrialized countries themselves. This is certainly a trend that will also have a positive impact on product availability in the long term.

Innovations in industrial manufacturing

Innovations in industrial manufacturing are developing rapidly. Major trends in Industry 4.0 are fundamentally the further development of IIoT products, high-performance sensors and actuators, and artificial intelligence applications.

In 2023, digital twin technology will continue to enrich industrial processes and put them to the test. In addition, the topic of energy efficiency, for example in the field of robotics and automation, will continue to be pushed both by researchers and within industrial companies. In order to guarantee resilient supply chains, the trend in 2023 is clearly moving in the direction of reshoring with regard to the location of production facilities.

In the online store of Bürklin Elektronik you will find high-quality sensors, actuators and various products in the field of IoT. If you have any questions about individual items, please contact our experts! We will be happy to help you.