Assembly of Electronic Components

Electronic manufacturing is the heart of the modern technology world and a complex matter that brings with it many challenges.

It is the basis for numerous applications that touch our daily lives – from consumer electronics to communication and industrial automation. Modern and innovative concepts such as the Internet of Things (IoT) and smart manufacturing are only made possible by this.

The application areas and topics are as diverse as the complex and detailed assembly of electronic components.

The Basics of Electronics Manufacturing: THT & SMT Assembly

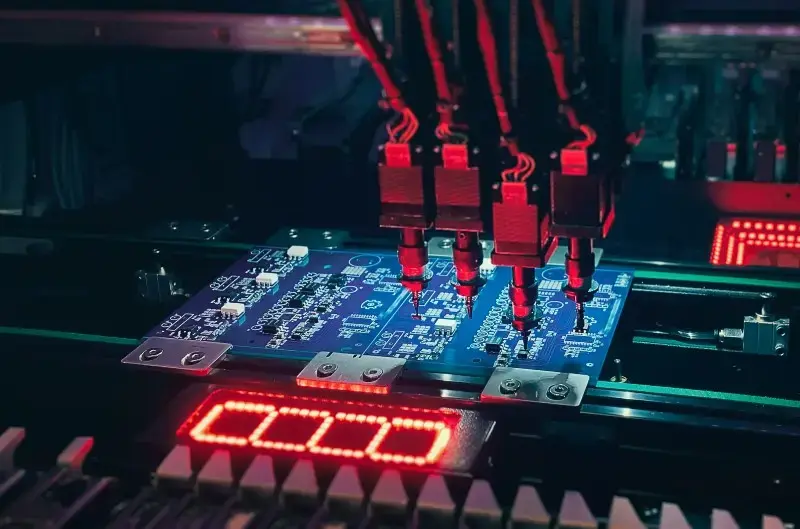

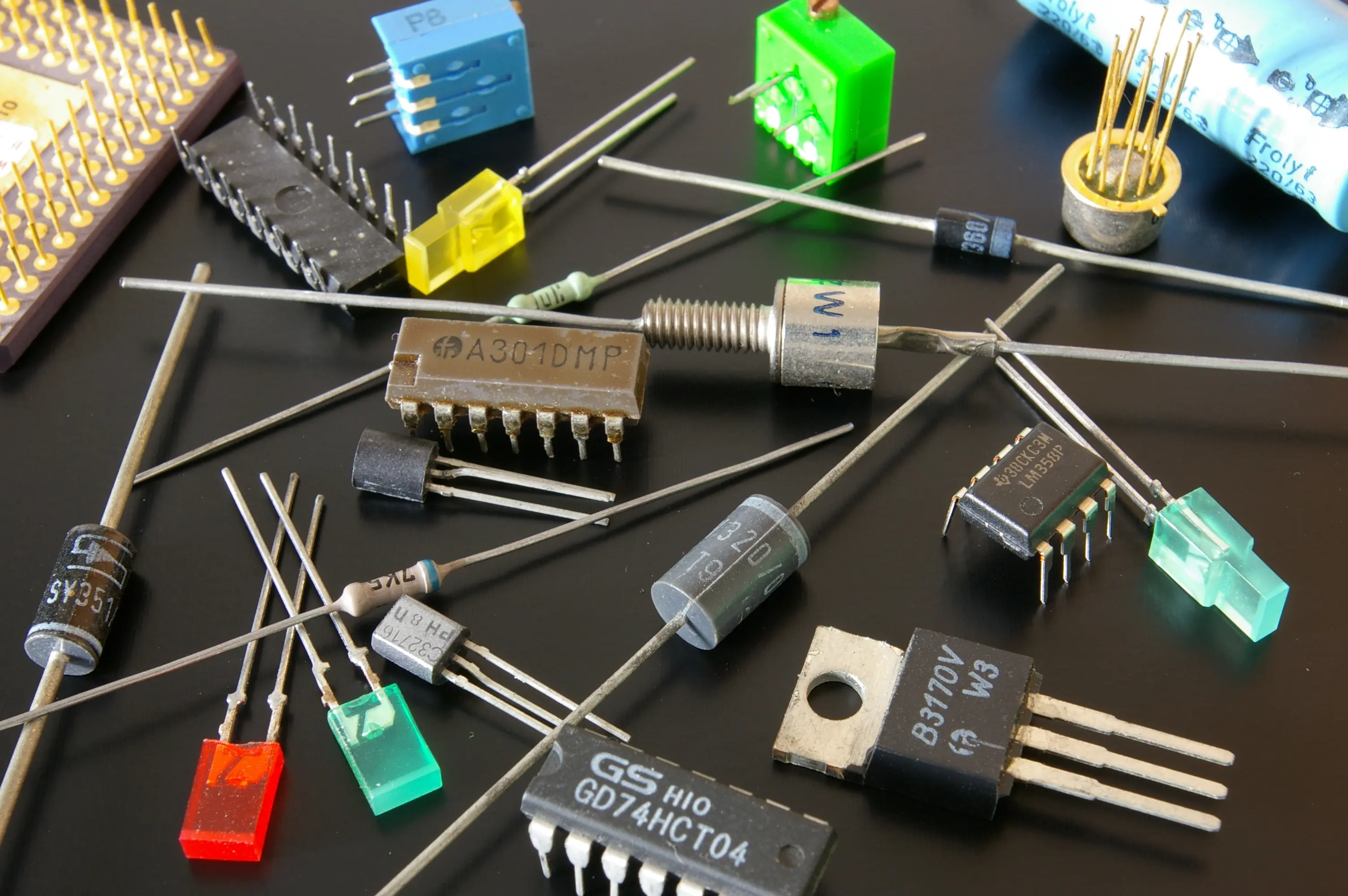

In the world of electronics manufacturing, the assembly technologies THT (Through-Hole Technology) and SMT (Surface Mount Technology) are indispensable elements.

In SMT assembly, the electronic components are soldered directly onto the printed circuit board. This type of manufacturing is suitable for higher packing density and for automatic assembly.

THT, on the other hand, is often used for applications that have specific mechanical requirements. Here, wired components are inserted through the printed circuit board and then soldered to the printed circuit board. This creates a strong connection between the components and the printed circuit board and is ideal for larger components.

Learn more in our guideAt Bürklin, we know that electronics manufacturing is a complex business with many challenges. That's why we offer you a wide range of electronic components – from printed circuit boards, connectors and capacitors to resistors, inductors, pushbuttons and fuses from well-known manufacturers.

Whether you need individual products, pick & place or contacts on reels, we ensure that your production line runs smoothly.

Preparation is everything, which is why we are also happy to support you in the preparation of materials. Benefit from our free reeling service, our e-procurement solutions or blanket orders and forward orders. Ensuring that you receive your components exactly when you need them.

Megatrend & Challenge: Miniaturisation – Innovation in the smallest of spaces

As technology advances, electronics are becoming smaller and more powerful. The trend towards miniaturisation demands high-quality components that are extremely powerful and as small as possible. Miniature components such as tiny resistors and capacitors make it possible to realise complex circuits in the smallest of spaces.

We stay on the cutting edge for you and take a detailed look at the trend of miniaturisation in our online magazine.

Everything about the megatrend

Staying on the Cutting Edge: Our Product Range for PCB Assembly

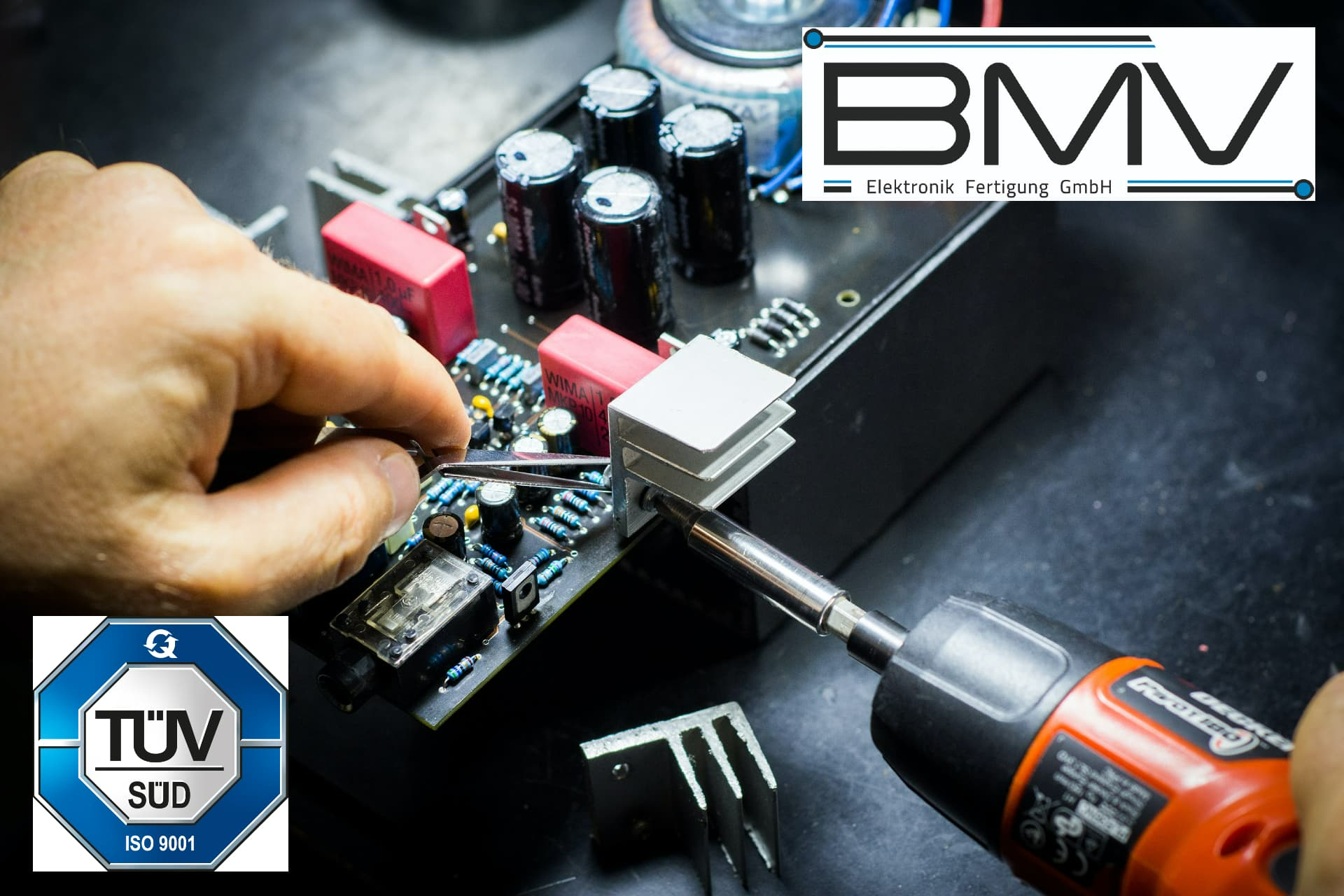

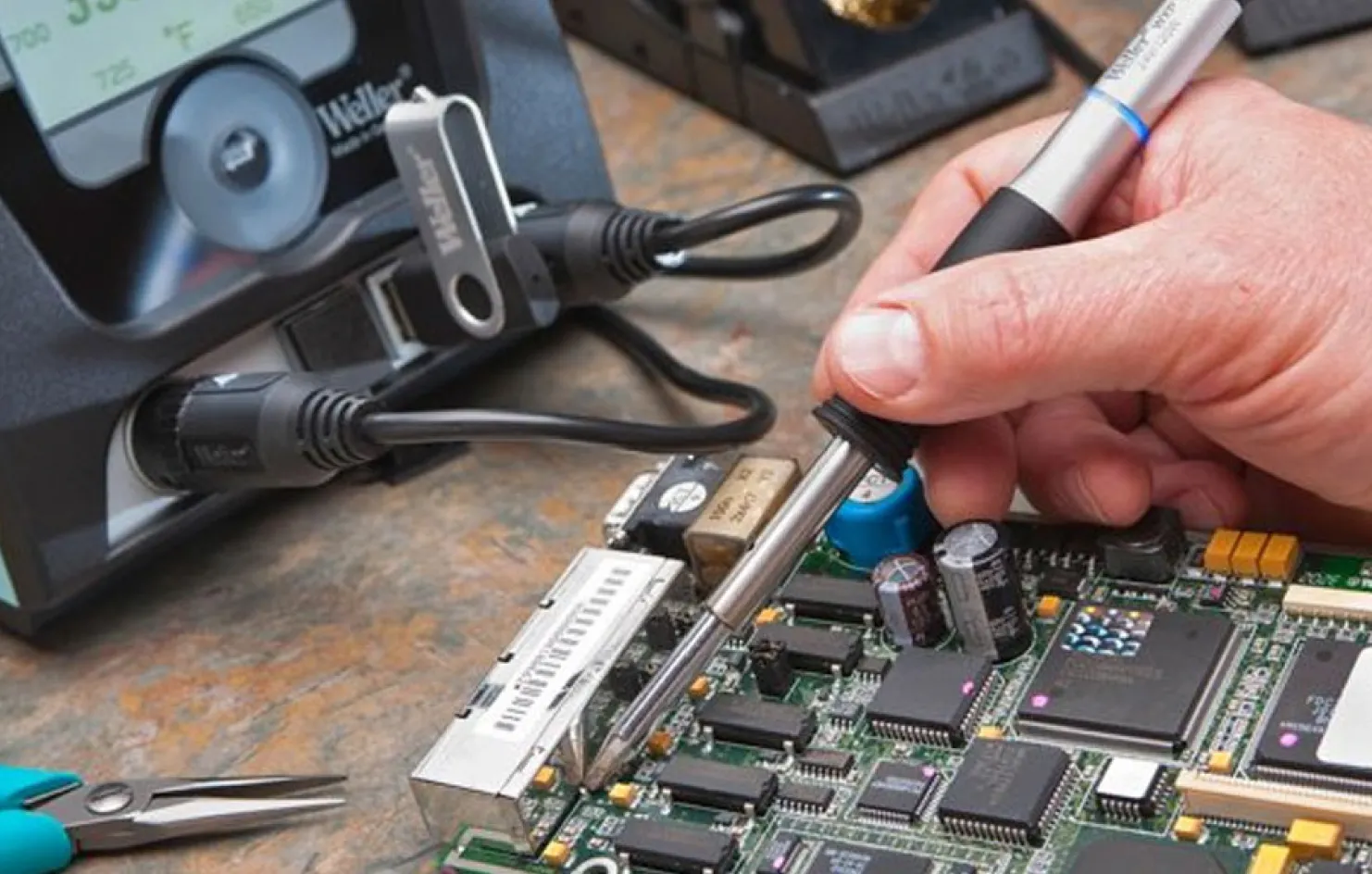

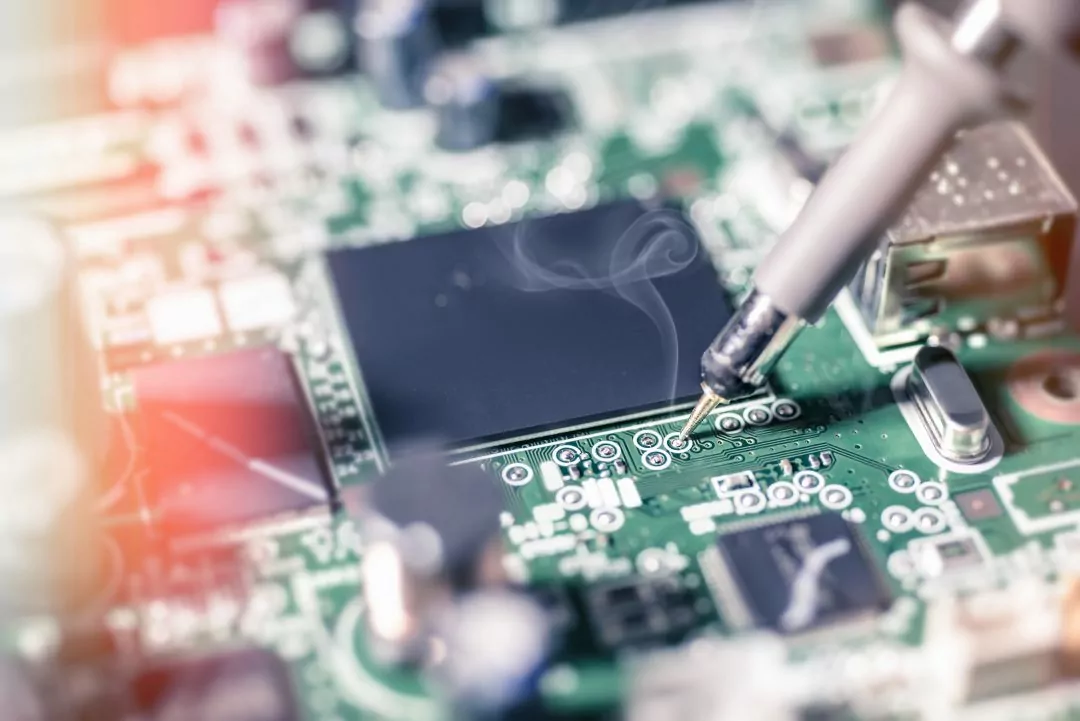

Attention to detail: soldering technology

Soldering technology is an essential element in electronics manufacturing. It ensures precise and robust connections. Due to increasing quality requirements and rapid advances in digitalisation and the IoT, soldering processes such as wave soldering or reflow soldering are experiencing an upturn. However, classic soldering processes remain important.

With soldering stations, magnifying lamps, tweezers and placement frames from top manufacturers such as Weller, Ersa and JBC, we offer everything you need for high-quality soldering.

Whether it's automated soldering of SMT components or manual reworking of three-dimensional THT components, we focus on quality and precision.

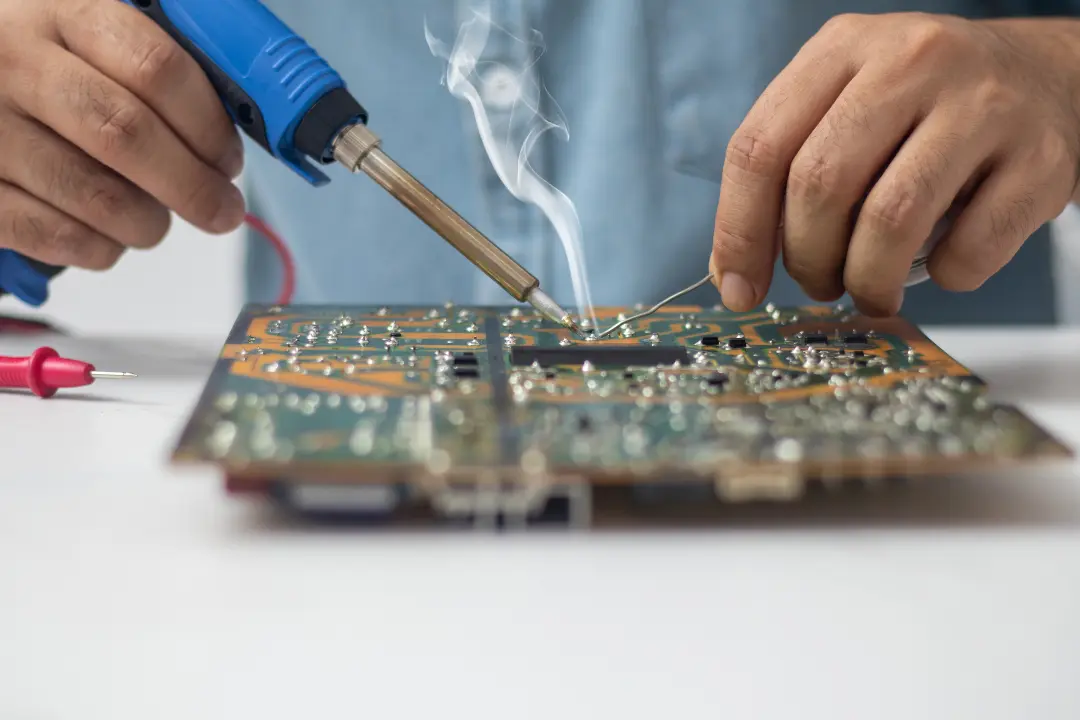

Solder fume extraction – Health is our top priority

The health of your employees is irreplaceable. That is why we offer you comprehensive solutions for occupational safety, especially for soldering processes.

Products from our selection of manufacturers ensure that smoke and harmful vapours generated during soldering are reliably extracted and the working environment remains safe. For clean air and healthy employees. Find out more in our magazine article!

View fume extraction solutionsDiscover our product portfolio for soldering technology

ESD protection: More than just a directive

ESD events regularly cause faults and failures in high-quality printed circuit boards. Targeted ESD protection measures are necessary to ensure product quality and to comply with the highest standards.

That's why we offer you the right products to protect your components against electrostatic discharges and guarantee the highest quality – from ESD soldering mats and kits to ESD clothing. Find out what other measures you can take in our blog post.

Learn more about ESD protectionDiscover our ESD product portfolio

After production is before testing: Quality inspection for the highest standards

Top quality is essential in electronics manufacturing. A thorough quality inspection ensures that your products meet the highest standards and function perfectly.

With the right inspection equipment, you can detect critical defects early on. And if the worst comes to the worst, our desoldering and rework stations provide a quick remedy.

Our product portfolio for quality inspection

Design for Manufacturability (DFM): easier, better, more efficient

Good design decisions start as early as the PCB layout phase. An effective DFM concept ensures that your products can be manufactured more easily, cost-effectively and to a higher quality. Design for Manufacturing focuses on optimising the parts and components list and standardising it. Other advantages include:

- Shortening the product development process

- Errors and defects are detected and eliminated at the beginning of the product life cycle

- Acceleration of production

- Lower production costs

With our free eCAD service, you can quickly and easily integrate the components you need into your PCB layout, making it easier, cheaper and higher quality to go into production.

Discover our eCAD service

Materials management: efficiency at all levels with Bürklin

In the highly networked and time-critical world of electronics manufacturing, smooth materials management is essential. The required components and materials must be available in the right quantity and quality at the right time.

With our forward orders and blanket orders, we help you to optimise your materials planning as efficiently as possible. In addition, Bürklin can help you minimising throughput times and keeping your storage areas small.

On top of that, our e-procurement solutions enable you to digitise and simplify the procurement of the components required, such as connectors or resistors. Reliable deliveries, optimised stock-keeping and short throughput times reduce your costs while at the same time increasing production efficiency.

Bürklin delivers: Your reliable partner for EMS

Click on a service to find out more about it.

Become part of our community!

Would you like to be informed about all the latest news in the field of assembly, electronics manufacturing and other topics? Then sign up for the Bürklin newsletter and look forward to receiving product recommendations, product news and other useful knowledge.

Customer-focused service

70 years of expertise

Customised procurement solutions

Regional location

Solutions from our manufacturers for high-quality assembly

Discover solutions from well-known manufacturers that will help you to achieve high-quality assembly of electronic components.

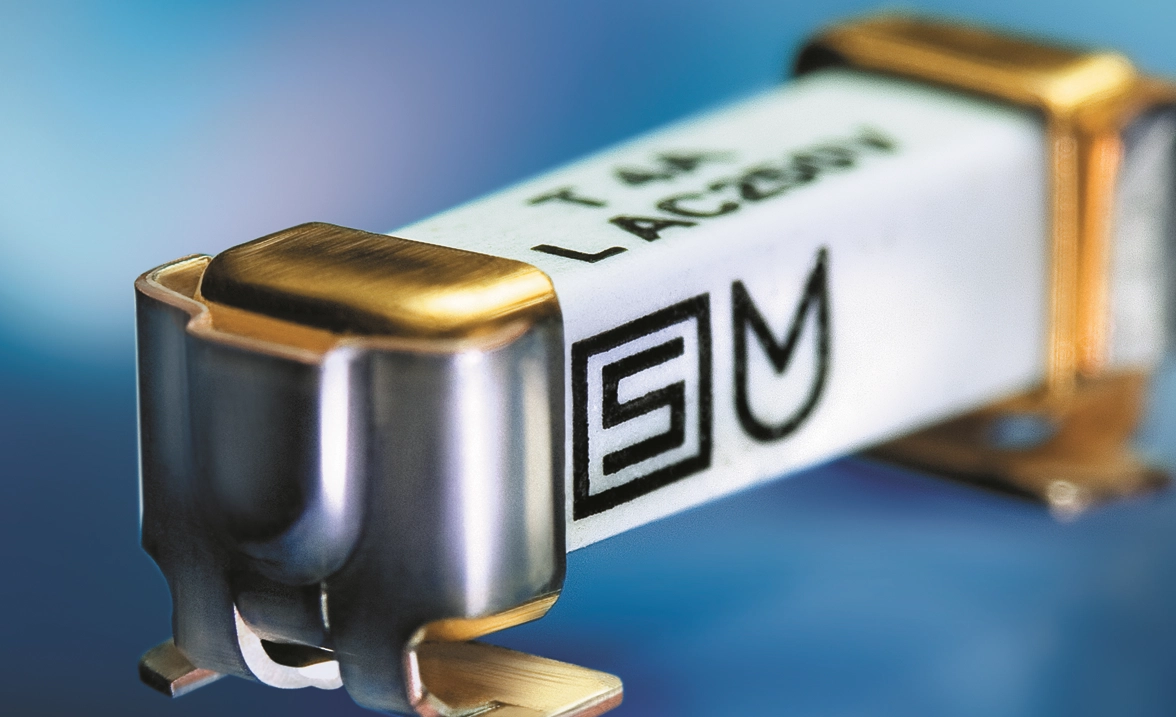

Fuses from SCHURTER: precise, compact and with low losses

Following the motto "Safety is our business", SCHURTER offers a wide range of different fuses for PCB assembly in the electronics industry.

SMD fuses: Reliable protection directly on the PCB

SMD fuses offer a compact and precise solution for primary and secondary protection directly on the printed circuit board. The UMF 250 series fuses are fast-acting SMD fuses that protect electronic systems from overcurrents and short circuits. The UMT 250 fuses are characterised by a high breaking capacity.

Thanks to their very small size, they are ideal for placement machines. The UMZ 250 miniature SMD fuses, on the other hand, offer maximum switching capacity with the smallest installation dimensions and enable easy replacement after the soldering process.

View SMD fuses from SCHURTERChip fuses: effective and compact protection

SCHURTER's chip fuses have been specially developed for secondary circuits and provide precise and low-loss overcurrent protection. Thanks to their solid construction, they are particularly resistant to vibrations and pulse loads.

With six different types in chip sizes from 0402 to 1206, the fuses provide compact and effective protection in the event of a fault. The USI 1206 chip fuse is the only one on the market with VDE approval. The gold-plated SMD contacts also make the chip fuses particularly suitable for storage and have a positive effect on contact quality.

The chip fuses are suitable for a wide range of applications, particularly for mobile and battery-operated devices in sensor technology and industrial electronics. They are also suitable for lead-free soldering processes, as they are both halogen-free and RoHS-compliant.

View chip fuses from SCHURTER

Compact components with high performance from APEM

The trend towards miniaturisation continues and compact applications with high safety requirements are in ever-greater demand. With the Ultramec series, APEM is responding to this trend and offering single-pole and 2-pole short-travel keyswitches that are particularly suitable for safety-critical functions in industrial remote control or for other devices with limited space.

The Dualmec switch from the Ultramec family is currently the smallest 2-pole switch on the market. The switch was specially developed to increase safety in hand-held devices and devices with limited space. Despite the 2-pole design, the switches are suitable for demanding applications.

The advantages of the small SMD component:

- Increased safety through double confirmation

- Compact

- Numerous design options with standard caps

- Easy alignment of front and printed circuit board with the help of sliding caps

- Precise switch positioning with positioning pins

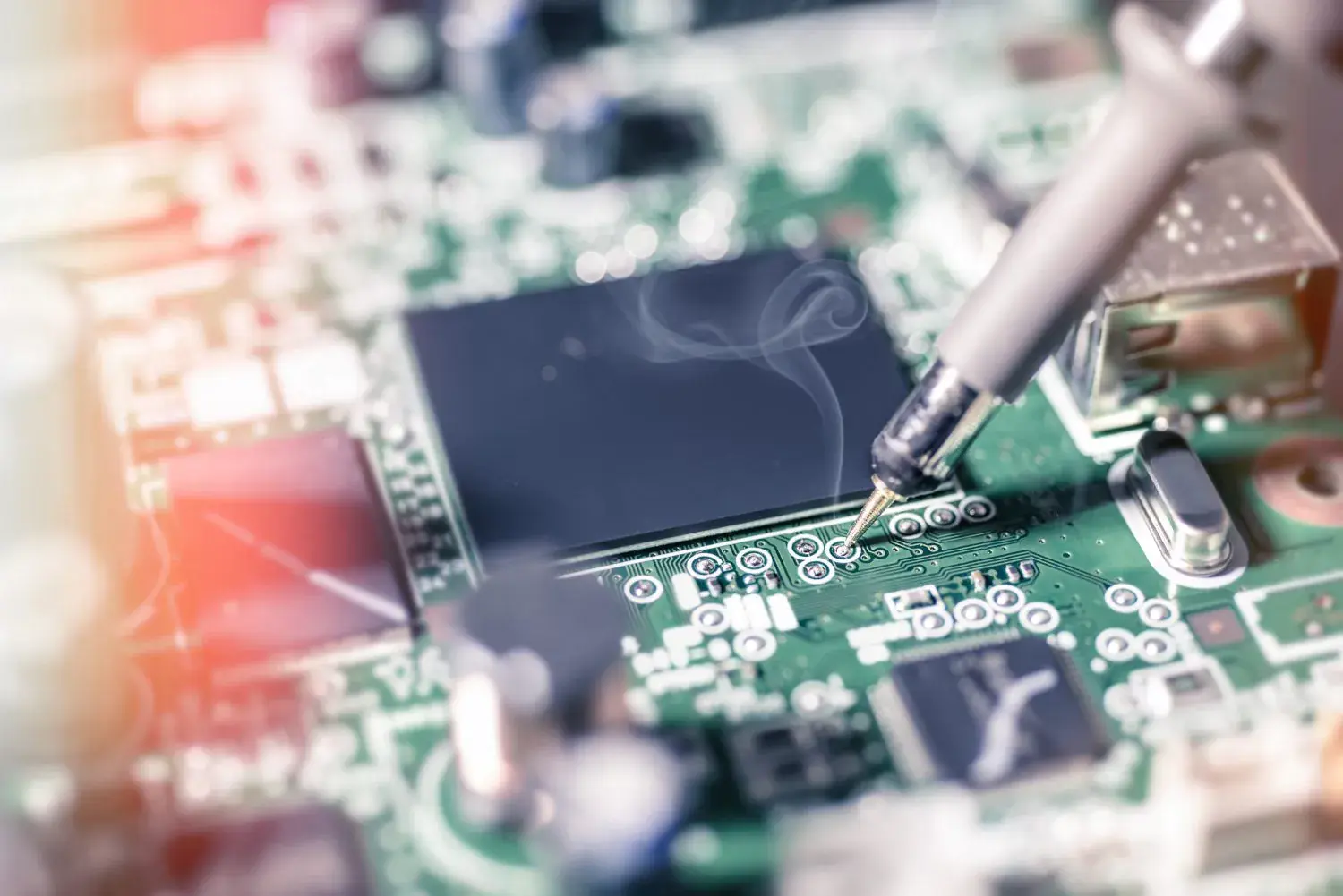

Drag soldering: Reworking with Weller

Reworking printed circuit boards is a necessary evil that often cannot be avoided. This makes it all the more important to have good soldering and reworking tools available at the workplace. Some components require a lot of time, training, skill and dexterity. A high number of pins and a fine grid can be a challenge even for experienced soldering technicians.

Point-to-point rework and soldering is a good process if only a few connections need to be reworked. If a large number of connections need to be soldered or the entire device needs to be moved and soldered, point-to-point soldering is too time-consuming.

An alternative to this is drag soldering, which produces very even solder joints. It is also very fast and easy to perform with a little training. However, it should be noted that drag soldering requires external liquid flux. This makes the cleaning process more complex to ensure that no flux residue remains on the assembly.

Reworking always involves effort and costs. However, the right technique and training, together with high-quality soldering equipment, ensure high quality, high yield and low costs for the end product. That is why we rely on the high-quality products from Weller.

View soldering technology from WellerSmart Tweezers from ideal-tek: redefining measurement and precision

Smart Tweezers redefine measurement and precision: they significantly simplify the testing and troubleshooting process. The Smart Tweezers from ideal-tek meet the highest standards and are as accurate as classic LCR meters. Thanks to their compact and ergonomic design, they are lightweight and can be operated with one hand – whether you are right- or left-handed.

With the Smart Tweezers, you can measure the capacitance, resistance, inductance and much more of electronic components. In addition, the device automatically recognises the component to be measured and selects the correct settings.

The perfect addition to the Smart Tweezers is the matching display. This allows you to view your data in real time and save it on a micro SD card or via the cloud. The display has 16GB of memory and runs on Android. The design of the display enables it to be used in the field or at the workbench.

A perfect fit for anyone who works with electronic components: easy to use, efficient and accurate.

View Smart Tweezers from ideal-tek

Video microscopes for quality inspection from Kern

For quality inspection of manufactured components, we recommend high-resolution video microscopes. The Kern OIV-3 was specially designed to optimise digital stereomicroscopy. As a result, the video microscope offers a well-thought-out complete solution for axial optics and enables direct and uncomplicated display of your samples on the screen.

The large working surface and the large display enable observation, analysis and documentation, even in industrial applications. An additional monitor can be connected via an HDMI interface. This allows live observation to be carried out on two devices operated in parallel.

The included LED incident light illumination allows you to optimally illuminate your sample, and the zoom wheels with integrated click-stop allow you to precisely select the magnification level. This makes it easy to calibrate the documentation functions in the software.

Discover video microscopesFrom Vision to Reality: Shaping the Future Together

From the PCB layout phase to the first assembly of your printed circuit boards, from miniaturisation and precise soldering to ensuring quality and occupational safety: we are your reliable partner at every step of the electronics manufacturing process.

With high-quality components from leading manufacturers and comprehensive services, we help you to achieve the highest standards and continuously improve your production processes. Together, we are shaping the future of electronics manufacturing – more efficiently, more safely and with higher quality.

A look behind the scenes: our successful partnerships

Guides for successful assembly

Electronics Manufacturing and its Challenges

Electronics manufacturing is a complex matter that presents many challenges. Circuit board assembly in particular presents electronics service providers with great difficulties. How can these challenges be overcome? And how can electronics manufacturing processes be automated in a simple and safe way?

Read now!

Soldering Stations Guide

A soldering station is a special version of a soldering iron. Soldering stations usually consist of three components: a power supply unit, the so-called soldering iron unit and the soldering iron. Before you buy a soldering station, you should think about modes of operation, specific characteristics and the different types, as well as necessary accessories. We have answered the most important questions and made specific recommendations on the subject of soldering stations.

Read now!

The Fascinating World of Tweezers: How to Choose the Right Ones

There is a wide range of different types of tweezers, with several hundred different models available. What are the main features that help you choose the right tweezers for the task at hand? We take a closer look at this fascinating world and give you tips on how to choose the right tweezers for your application.

Read now!

ESD Protection Measures at the Workplace

To prevent electronic components from being damaged by electrostatic discharges, targeted ESD protection measures are necessary in the workplace. But which measures are really effective? In this article, you will find everything you need to know about ESD protection in the workplace - from the right clothing and suitable tools to optimal room design.

Read now!

Solder fume extraction

Toxic solder fumes are a serious health hazard for people working in the electronics industry or involved in soldering. The toxic fumes can lead to respiratory illness, cancer and other health problems. We take an in-depth look at the risks of toxic solder fumes and show you how to protect yourself.

Read now!Know How Hub: Electronics Manufacturing

We take a closer look at the relevant topics in the field of electronics manufacturing for you in our online magazine "Blickpunkt Elektronik Kompetenz". From how a soldering station works to the assembly and manufacture of active components to material know-how for various manufacturing processes: We offer you extensive first-hand expertise on all aspects of electronics manufacturing for you to read.

Explore our Know How Hub

FAQ: Assembly of Electronic Components

What does assembling mean?

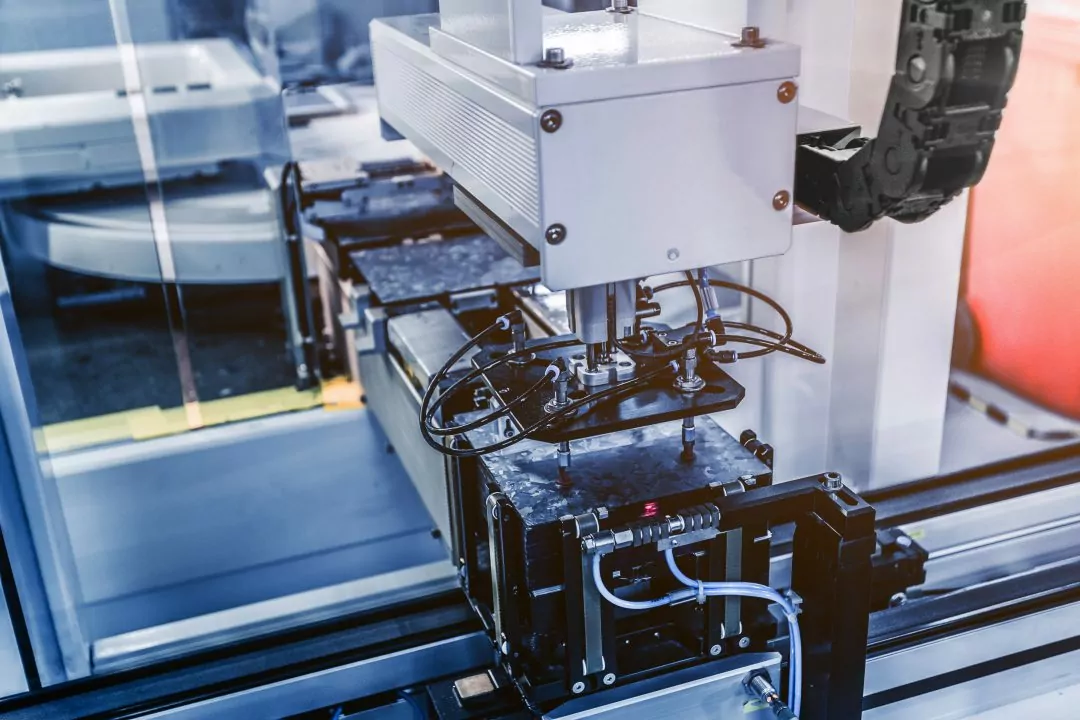

Assembly is the process by which electronic components are placed and attached to a printed circuit board (PCB). This can be done manually or by machine.

How does the assembly of SMD printed circuit boards (PCBs) work?

The assembly of SMD circuit boards is usually done by machine. Solder paste is applied to the PCB using a solder paste printer. The SMD components are then placed on the PCB using an automatic placement machine. The PCB is then heated in a reflow oven, which melts the solder paste and firmly bonds the SMD components to the PCB.

What tools are required for the assembly of electronic components?

The tools required for assembling electronic components depend on the type of assembly (manual or machine) and the components used. Tweezers, soldering irons and solder are typically required for manual assembling. Automatic assembly machines, solder paste printers and reflow ovens are required for machine assembling.

What are the most common problems when assembling electronic components and how can they be avoided?

The most common problems when assembling electronic components include incorrectly placed or reversed polarity components, solder joint errors and short circuits. These problems can be avoided by using suitable tools, following assembly guidelines and carefully monitoring the equipping process.

What is the difference between SMD assembly compared to traditional methods?

The advantages of SMD components are that they are smaller and lighter, making the PCBs smaller and more compact. SMD assembly also enables a higher packing density on the circuit board. SMD components are also often cheaper than THT components.

Which test methods are used to check the quality of the assembly?

The test methods include visual inspections, electrical tests and X-ray tests. Visual inspections are used to detect incorrectly placed or reversed polarity components. Electrical tests are used to check the function of the assembly circuit board. X-ray tests are used to detect defects inside the PCB.